Կառուցվածքային ամբողջականություն և դիմացկունություն

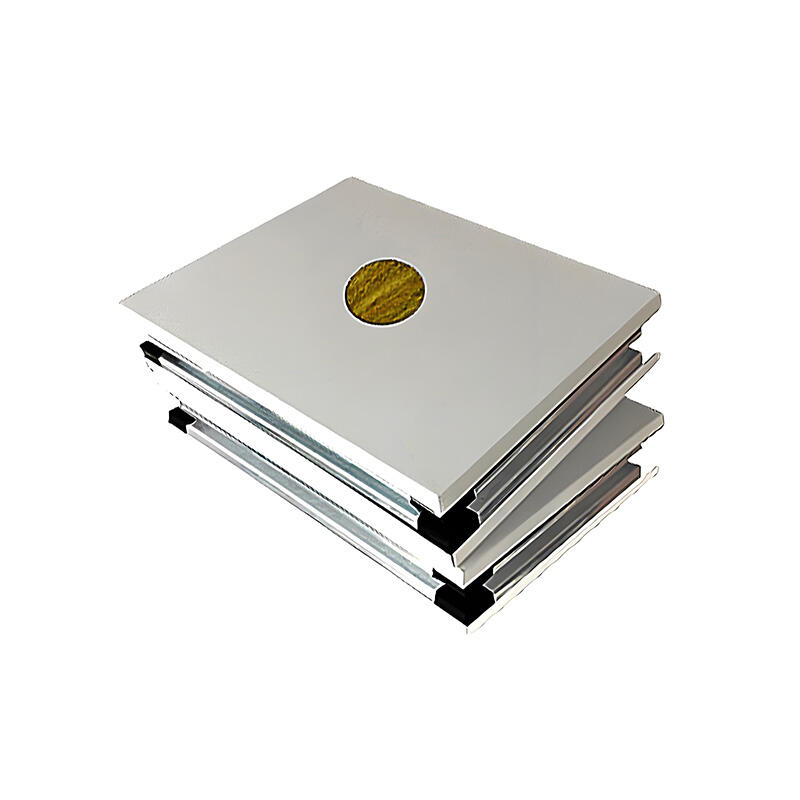

Սիլիկայի սենդվիչ տախտակների նորարարական դիզայնը ներառում է բարձր ամրության արտաքին շերտեր, որոնք ապահովում են բացառիկ կոնստրուկտիվ ամբողջականություն՝ պաշտպանելով մեկուսացնող միջուկը։ Այս տախտակները ցուցադրում են մեխանիկական լարումների, հարվածների և միջավայրի ազդեցության նկատմամբ արտաքին դիմադրություն, ապահովելով երկար ծառայության ժամանակ նվազագույն նորոգման պահանջներով։ Կոմպոզիտային կառուցվածքը ստեղծում է կոշտ, սակայն թեթև տախտակ, որը կարող է ծածկել նշանակալի հեռավորություններ առանց լրացուցիչ աջակցության, ինչը նվազեցնում է տեղադրման բարդությունը և կոնստրուկտիվ բեռնվածությունը։ Տախտակների դիմադրությունը խոնավության թափանցմանը կանխում է ներքին վատթարացումը և պահպանում է կյանքի ընթացքում հաստատուն արդյունքները։ Նրանց կարողությունը դիմանալ տարբեր եղանակային պայմանների, ներառյալ էքստրեմալ ջերմաստիճանները, ՈՒՖ ճառագայթումը և քիմիական ազդեցությունը, դրանք դարձնում է իդեալական ընտրություն ինչպես առևտրական, այնպես էլ արդյունաբերական կիրառումների համար։ Այս տախտակների տևականությունը թույլ է տալիս նվազեցնել նորոգման ծախսերը և երկարացնել փոխարինման ընթադրական ժամանակահատվածները, ապահովելով հիանալի երկարաժամկետ արժեք։