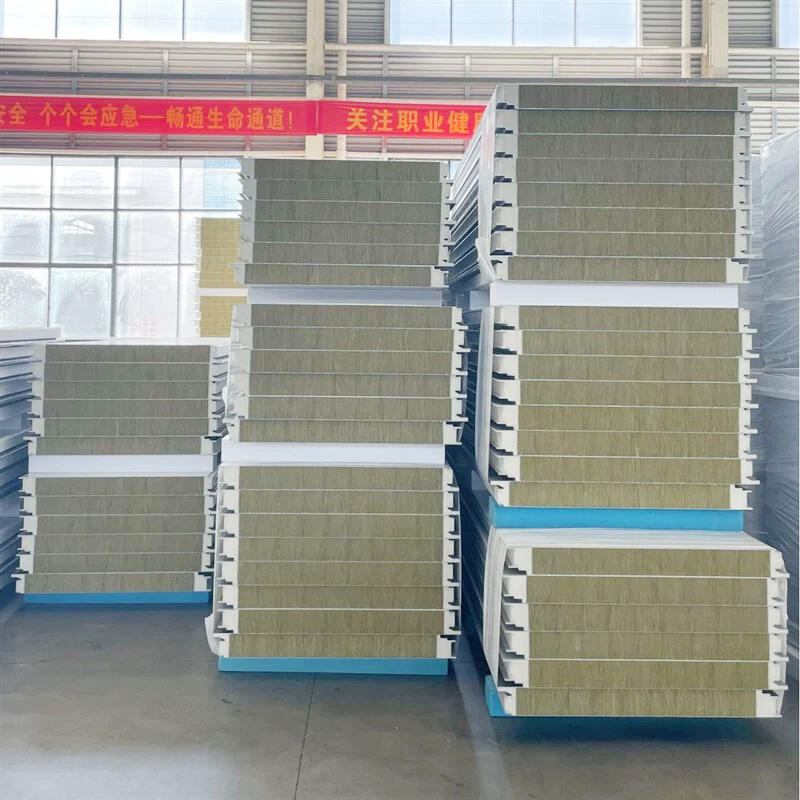

הכרת פתרונות בנייה מתקדמים באמצעות טכנולוגיית לוחות סנדוויץ'

התעשייה הביניה עברה אבולוציה משמעותית בחומרי בנייה ובשיטות הבנייה במהלך העשורים האחרונים. בין ההישגים הטכנולוגיים הללו, צצו לוחות סנדוויץ' כפתרון מהפנט המשלב יעילות, קיימנות ותועלת כלכלית. רכיבי בנייה גמישים אלו מורכבים מחומרי פנים מחוברים ללב קליל, ו יוצרים מבנה המציע יתרונות רבים עבור פרויקטים בינוי בגדלים שונים.

בبيئة הבנייה המהירה של ימינו, פונים בונים וمهندסי בניין בתדירות הולכת וגדלה ללוחות סנדוויץ' כבחירתם המועדפת לדפנות, גגות ויישומים מבניים שונים. הפופולריות הגוברת של הלוחות האלה נובעת מהשילוב הייחודי שלהם של שלמות מבנית ויתרונות מעשיים הפונים לאתגרים בנייה מודרניים.

יתרונות מרכזיים של בנייה בלוחות סנדוויץ'

תכונות יוצאות מן הכלל של חימום תרמי

אחת התרונות המשמעותיים ביותר של לוחות סנדוויץ' היא היכולת המצוינת שלהן לבודד חום. החומר הליבה, שברוב המקרים מורכב מפולי אוריתן, פוליאיזוסיאנורט או צמר מינרלי, יוצר מחסום יעיל נגד העברת חום. יעילות תרמית זו תורמת לצמצום צריכה של אנרגיה לצורך חימום וקירור, מה שמוביל להפחתת עלויות תפעול של מבנים לאורך מחזור החיים שלהם.

בניינים שנבנו בעזרת פנלים סנדוויציים יכולים לשמור על טמפרטורות פנימיות נעימות עם מינימום השקעת אנרגיה. יעילות הבידוד תורמת לא רק ליציבות הסביבתית אלא גם עוזרת לממשיכי רכוש להרוויח חיסכון משמעותי על חשבונות האנרגיה שלהם. הביצועים התרמיים של פנלים סנדוויציים הם לעיתים קרובות מוכרים על פני חומרי בנייה מסורתיים.

חוזק מבני ועיצוב קליל

למרות המשקל הקל יחסית שלהם, הפנלים הסנדוויציים מציגים חוזק מבני יוצא דופן. שילוב של חומרי פנים חזקים ולב מותאם במדויק יוצר מבנה מרוכב המסוגל לעמוד בטענים משמעותיים תוך כדי שהוא קל בהרבה ממסורות בנייה מסורתיות. תכונה זו הופכת את הפנלים הסנדוויציים לחשובים במיוחד בפרויקטים בהם יש הגבלות משקל.

המַעֲטַת הַמִּשְׁקָל שֶׁל הַפַּנְלִים הַמְּרֻכָּבִים מְפַשְׁטָה אֶת תְּהלִיכֵי הַהֶעָבָרָה וְהַהַתקְנָה, מְחַסֶּכֶת זְמַן בִּנְיָן וּפְעֻלּוֹת. לְבַד מִכֵּן, הַמִּשְׁקָל הַמְּעוּטָף מַטִּיל פָּחוֹת לָחַץ עַל יְסַד הַבִּנְיָן, מַשְׁאִיר אוֹפְּצִיָּה לְחִיסְכוּי בְּצֹרֶךְ הַתּוֹמְכוֹת הַבִּנְיָנִיּוֹת.

יתרונות התקנה והוצאות

תהליך הקמתה והתקנתה מהיר

הַטִּיב הַמּוֹדוּלִי שֶׁל הַפַּנְלִים הַמְּרֻכָּבִים מַפְנִימָה אֶת זְמַן הַבִּנְיָן. הַפַּנְלִים נִבְצְרוּ לְהִתְקָנָה מְהִירָה וּפְשׁוּטָה, לָכֵן לָהֶם מְכָנִיזְמִים מְחַבְּרִים שֶׁמְּאַפְשְׁרִים הַרכָּה מְהִירָה. צוּמַת מְעַט תּוּכַל לְהַתִּיק פַּנְלִים גְּדוֹלִים לַחֹמָה אוֹ לַגָּג בְּשִׁבְרֵי הַזְּמַן הַמֻּטָּל בִּשְׁלוּל שִׁיטוֹת הַבִּנְיָן הַמְּסוּרְתוֹת.

הַתְּהלִיךְ הַמְּהִיר שֶׁל הַהַתקְנָה מְחַסֵּךְ לֹא כְּמוֹ פְּעֻלּוֹת אֶלָּא גַּם מְקַצֵּר אֶת זְמַן הַמְּשִׁימָה הַכּוּלִי. הַגְמָרַת הַמְּשִׁימָה בְּזְמַן מְקֻדָּם מַשְׁמַעַת תְּקָבַת מִשְׁרָה וְהַחְלָפַת הֶחָסַךְ לְמוֹרֵי נְכָסִים וּמְפַעֲנֵי הַשִּׂכְרוּת. לְבַד מִכֵּן, תְּהלִיךְ הַהַתקְנָה הַפָּשׁוּט מְחַסֵּךְ אֶת סִכּוּי הַשְּׁגוּאוֹת וְצָרִיךְ מְחַבְּרִים מְתֻקְשָׁנִים.

יעילות עלויות ארוכת טווח

למרות שהמחיר ההתחלתי של פנלים סנדוויציים עשוי להיראות גבוה בהשוואה לחומרים מוסכמים מסוימים, היתרונות הכלכליים לטווח הרחוק הופכים אותם לבחירה rentable. שילוב של ירידה בצריכת אנרגיה, דרישות מזעריות לתפעול ואריכות חיים ממושכת תורמים לחיסכון ניכר לאורך זמן.

העמידות של הפנלים הסנדוויציים מבטיחה פחות תיקונים וחליפות בתקופת חיי הבניין. התנגדותם לגורמים סביבתיים וליציבות מבנית מבטיחה שהבניינים ישמרו על שלמותם ומראה חיצוני כמעט ללא התערבות, וכך יקטינו משמעותית את הוצאות התפעול.

היבטים סביבתיים וקליניים

יעילות אנרגטית וטביעת פחמן

בעידן שבו תודעה סביבתית מובילה את החלטות הבנייה, פנלים סנדוויצ'יים בולטים בזכות תרומתם לניהול בנייה בר-קיימא. התכונות המצוינות של פנלים אלו כמבודדים מקטינות בצורה משמעותית את צריכת האנרגיה הנדרשת לבקרת האקלים, מה שמשתלם ישירות בהפחתת הפליטה של פחמן במהלך חיי הפעילות של הבניין.

רבות מפנלי הסנדוויץ' מיוצרים תוך שימוש בחומרים ובתהליכים המתחשבים בסביבה. היכולת למחזר רכיבים בסוף תקופת השירות שלהם מעצימה את תעודות הסביבה שלהם, מה שעושה אותם לבחירה מושכת עבור פרויקטים של בנייה ירוקה.

הפחתת פסולת ויעילות חומרים

ייצור מדויק של פנלי סנדוויץ' ממזער את הפסדי החומרים בתקופת הייצור וההתקנה. בשונה משיטות בנייה מסורתיות שבעזרתן נוצרת לעיתים קרובות פסולת רבה באתר, בנייה באמצעות פנלי סנדוויץ' יוצרת מיעוט של פסולת. יעילות זו לא רק שמקטינה את ההשפעה הסביבתית, אלא גם תורמת לאתר בנייה נקי ומסודר יותר.

הסביבה המנוהלת של המפעל שבו מיוצרים פנלי הסנדוויץ' מבטיחה איכות אחידה תוך כדי אופטימיזציה של השימוש בחומרים. הגישה השיטתית לייצור עוזרת לשמר משאבים ולקטין את הדפוס הסביבתי של פרויקטים בניהליים.

שאלות נפוצות

כמה זמן פאנלים סנדוויציים נוטים לשרוד בדרך כלל?

עם התקנה ושיקום תקינים, פנלים סנדוויציים יכולים לשרוד 25–30 שנים או יותר. קיימם תלוי בגורמים כגון תנאי הסביבה, דפוסי השימוש ואיכות ההתקנה. יצרנים רבים מציעים אחריות בת 10 עד 15 שנים, מה שמראה על ביטחון בקיימם של המוצרים שלהם.

האם ניתן להשתמש בפנלים סנדוויציים בכל תנאי האקלים?

הפנלים הסנדוויציים נועדו לפעול בתנאי אקלים מגוונים, מהקצף הקשה ועד לסביבות החמות. קיימות חומרים שונים ליבתיים ואפשרויות פנים שמתאימות לצרכים אקלימיים מסוימים. עם זאת, חשוב לבחור פנלים עם מפרט טכני מתאים לתנאי המזג האוויר המקומיים ולדרישות הבנייה.

האם הפנלים הסנדוויציים עמידים בפני אש?

רבים מהפנלים הסנדוויציים מיוצרים עם תכונות של עמידות באש ותואמים את תקני הבטחה קפדניים בבנייה. רמת עמידות האש תלויה בחומרים הנמצאים במבנה הפנל, ובפרט בחומר הליבה. פנלים עם ליבת צמר מינרלי מציגים בדרך כלל עמידות באש טובה בהשוואה לאפשרויות אחרות. יש לבדוק תמיד את מדרגת האש המצוינת בפנלים לפני בחירתם לפרויקט.