הכרת גמישותם של חומרי בנייה מודרניים

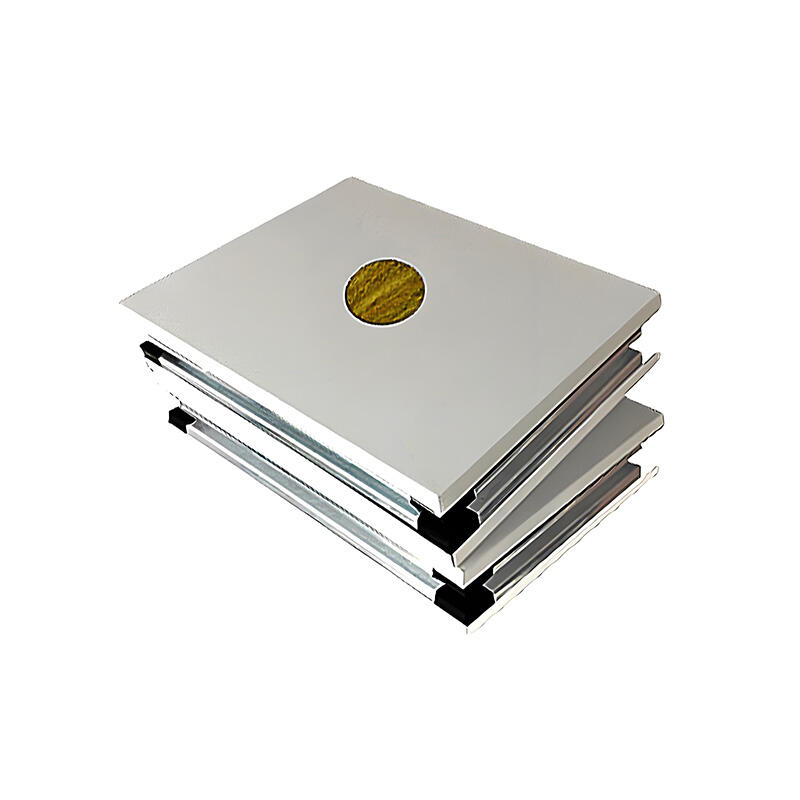

פאנלים סנדוויציים פוליאוריתניים שינו את תעשיית הבנייה וחומרי הבנייה בזכות שילובם יוצא הדופן של בידוד תרמי, שלמות מבנית ויעילות כלכלית. חומרים מרוכבים חדשניים אלו מורכבים משכבת פנים חיצונית משני הצדדים מחוברת ללב פוליאוריתני, ו יוצרים פתרון בנייה חזק ויעיל שנמצא בapplications רבות בזקפים שונים.

הדרישה הגוברת לחומרי בנייה חוסני אנרגיה וברורים דחפה את פנל הסנדוויץ' פוליאוריתן לקדמת הבמה במבנה המודרני. תכונות ה тепло החזקות שלהם, המשקל הקל וההתקנה המהירה הופכות אותן לבחירה אידיאלית הן בפרויקטים חדשים והן בשיקום מבנים קיימים.

יישומים תעשייתיים ומסחריים

אחסון קרה ו facilitation לעיבוד מזון

אחת היישומים החשובים ביותר של פנלי סנדוויץ' פוליאוריתאנים היא באחסנים קרים וב facilitation לעיבוד מזון. תכונות הבידול התרמי היוצאות דופן של הפנלים הופכות אותם לאידיאליים לשמירה על טמפרטורות קבועות בחדרי קור, קפפות ואזורים לעיבוד. תקנות התעשייה המזון דורשות שליטה קפדנית בטמפרטורה, ופנלי סנדוויץ' פוליאוריתאנים מצטיינים ביצירת סביבות שמענות על דרישות קפדניות אלו תוך מינימום צריכה של אנרגיה.

לוחות אלו מספקים גם התנגדות גבוהה ללחות וקל לנקות אותם, מה שעושה אותם תואמים לסטנדרטים של ביטחון המזון. משטח חלק וחסימת חדירת חיידקים מקשה על התרבותם ופועלת תחזוקה, שני גורמים קריטיים בסביבות עיבוד מזון.

מחסנים ומרכזי הפצה

מחסנים מודרניים ומراكז הפצה משתמשים רבות בלוחות סנדוויץ' פוליאוריתן במבנה שלהם. מתקנים אלו דורשים מרחבים פתוחים גדולים עם סביבת פנים מבוקרת, והלוחות מציעים פתרון יעיל הן ליישומים בקיר והן בגג. תהליך ההתקנה המהיר מקצר את משך הבנייה, בעוד שהמשקל הקל של הלוחות מאפשר טווחים גדולים יותר מבלי צורך במבנים תמיכתיים כבדים.

עומקן של פוליאוריתן מובטח ביצועים לאורך זמן facilities אלו בעלי תנועה רבה, ומסוגלת לעמוד בבلى יומיומי תוך שמירה על תכונות הבידוד שלה. תכונות הדלקה שלה תורמות גם הן לבטחון הבניין בכלל, עמידה בתקני הבנייה המסחריים ודרישות הביטוח.

יישומים בבניית מגורים

פתרונות בנייה לדירות מודרניות

בבנייה מגורית, פנלי פוליאוריתן הופכים לפופולריים הן בבנייה חדשה והן בפרויקטים של שיקום. בעלי בתים וcontractors מעריכים את הפנלים על תכונות התרמיות הגבוהות, אשר מפחיתות משמעותית את עלויות החימום והקירור. הפנלים יוצרים סביבת מגורים נעימה תוך תרומה ליעילות האנרגטית הכוללת של הבית.

מכותלי החוץ ועד מערכות הגג, הלוחות הרגילים הללו מציעים לאדריכלים ולמעצבים גמישות ביצירת חללים מגורים אסתטיים. הלוחות מגיעים בגימורים וצבעים שונים, מה שמאפשר התאמה אישית תוך שמירה על היתרונות הפונקציונליים המרכזיים שלהם.

מרחבי גراج וסדנאות

מוסכים ומעבדות מגורים נהנים רבות מפלטות שיפועיות פוליאוריתן. מרחבים אלו דורשים לעת קרובות שליטה בטמפרטורה ועמידות, ולכן הפלטות הן בחירה מצוינת הן לגדרים והן לתקרות. הבנייה העייפה של הפלטות עמידה בדרישות של סביבות עבודה תוך כדי שמספקת בידוד חיוני לנחות לאורך כל השנה.

קלות ההתקנה ודרישות התחזוקה הנמוכות הופכות את הלוחות למשיכה במיוחד לאוהבי DIY ולבעלי בתים המעוניינים להגביר את יעילות מרחב העבודה שלהם. תכונת הבליטה של הלוחות בהפחתת רעש תורמת גם להפחתת העברת רעש, שיקול חשוב עבור גراجים וסדנאות מחוברים.

יישומים כפריים וחקלאיים

אכסון בעלי חיים ואחסנה

מבנים חקלאיים, ובפרט אלו המאכסנים בעלי חיים או מאחסנים מוצרים רגישים לטמפרטורה, משתמשים באופן נרחב בפאנלים סנדוויציים של פוליאוריתן. הפאנלים יוצרים תנאים אידיאליים לרווחת בעלי החיים על ידי שמירה על טמפרטורות יציבות ופקוח מעולה על התרוואה. התנגדות הפאנלים לתנאי סביבה קשים ולכימיקלים חקלאיים מבטיחה את קיימתם באתרי חוות.

facilitiotes איחסון למוצרים חקלאיים, זרעים וציוד גם כן מפיקות תועלת מה właściות הגנה של הפאנלים. היכולת לשמור על רמות ספציפיות של טמפרטורה ו לחות עוזרת לשמירה על איכות המוצר תוך הפחתת עלויות אנרגיה הקשורות לבקרת האקלים.

אכסון ציוד ומכונות

מבנים כפריים המשמשים לאחסון ציוד חקלאי יקר ומכשור נעשים בעזרת פנלים סנדוויציים של פוליאוריתן לשם הגנה מפני מזג האוויר. קשיחותם של הפנלים ועמידותם באלמנטים הסביבתיים עוזרים להגן על נכסים יקרים, תוך כדי שמספקים מרחב עבודה נעים לבטיחות ולإصلاحים.

למבנים כאלו יש לעיתים קרובות צורך בפנסים ארוכים ובazים פתוחים, ומאחר שפנלים סנדוויציים של פוליאוריתן קלים במשקלם הם אידיאליים ליישומים מסוג זה. תהליך ההתקנה המהיר של הפנלים גם ממזער את הפרעה לפעילות החקלאית במהלך פרויקטים של בניה או הרחבה.

שאלות נפוצות

כמה זמן נמשכת בדרך כלל חיי השירות של פנלים סנדוויציים של פוליאוריתן?

פלטות סנדוויץ' מפוליאוריתן, כאשר מותקנות ומשומרות כראוי, יכולות להחזיק 25–30 שנה או יותר. קיימן תלוי בתנאי הסביבה, דפוסי השימוש ואמצעי השמירה. בדיקות שוטפות ושמרנות מתאימה יכולים להאריך משמעותית את משך חיי השירות שלהן.

האם פנלים סנדוויציים של פוליאוריתן הם ידידותיים לסביבה?

כן, פנלים סנדוויצ'יים מפוליאוריתאן תורמים ליציבות הסביבתית בזכות תכונות היעילות האנרגטית שלהם ואריכות ימיהם. הם עוזרים בהפחתת צריכת האנרגיה בבניינים, וכבר היום משתמשים בתהליכי ייצור ידידותיים לסביבה וחומרים שניתנים لإعادة ההליכה במבנה שלהם.

מה תחזוקה נדרשת לפנלים סנדוויצ'יים מפוליאוריתאן?

דרישות התחזוקה לפנלים סנדוויצ'יים מפוליאוריתאן מינימליות. ניקוי שגרתי עם פתרונות מתאימים, בדיקה תקופתית של חיבורים וח sealsרומים, ותיקון מיידי של כל נזק הם לרוב מספיקים לשמירה על הביצועים והמראה שלהם. הפנלים עמידים בפני קורוזיה ואינם זקוקים לצביעה או טיפולי שטח.