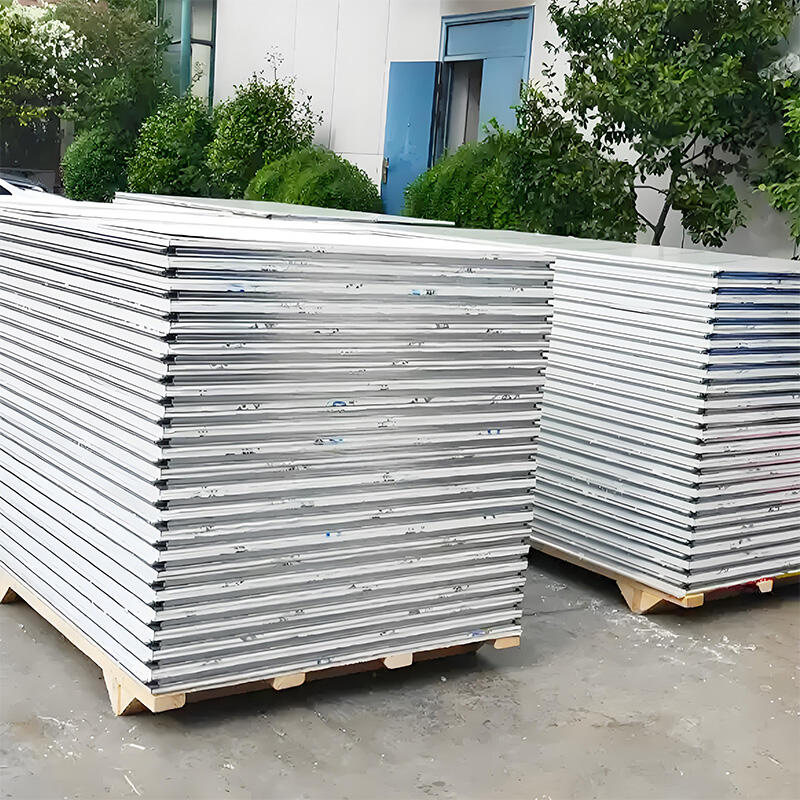

פנל סנדוויץ' ידני מבד שטיח

פאנלים סנדוויצ'יים מיוצרים 손ית מייצגים פתרון בנייה מתקדם המשלב בידוד מתקדם עם שלמות מבנית. הפאנלים מורכבים משלוש שכבות: שני פנים של פליז פלדה בעלי חוזק גבוה שסנדוויצ'ים ליבה של בדולח סלעי מודבק בקפידה. תהליך הייצור, אם כי מיוצר ביד, עוקב אחרי מפרט טכני מדויק כדי להבטיח איכות וביצועים אחידים. הליבה של הבדולח, שמיוצרת מאבן הבזלת טבעית, מספקת בידוד תרמי יוצא דופן עם ערכי R הנעים בדרך כלל בין 3.5 ל-4.0 לאינץ' סntity. הפאנלים מצטיינים בהתנגדות לאש, והם שומרים על שלמות מבנית עד ארבע שעות בטמפרטורות קיצוניות, מה שעושה אותם לאידיאליים למבנים הדורשים תקנים קפדניים של ביטחון. לפאנלים יש חיבורים מסוג צפה ושקע שיוצרים חותם אווייט נשלם בעת הרכבה, מה שמשפר את יעילות החום והתנגדות לאלים. גיוון השימוש שלהם מאפשר התקנה אנכית ואופקית, ומספק פתרונות למגוון עיצובים ארכיטקטיים ודרישות בנייה. עובי הפאנלים נע בדרך כלל בין 50 מ"מ ל-200 מ"מ, ומציע גמישות בסיוע לדרישות בידוד שונות, תוך שמירה על פרופיל קל משקל יחסית. טווח השימוש שלהם מתרחב מעבר לתכונות תרמיות, וכולל בידוד אקוסטי מעולה ותנגדות לחות, מה שעושה אותם למתאימים לתנאי סביבה מגוונים.