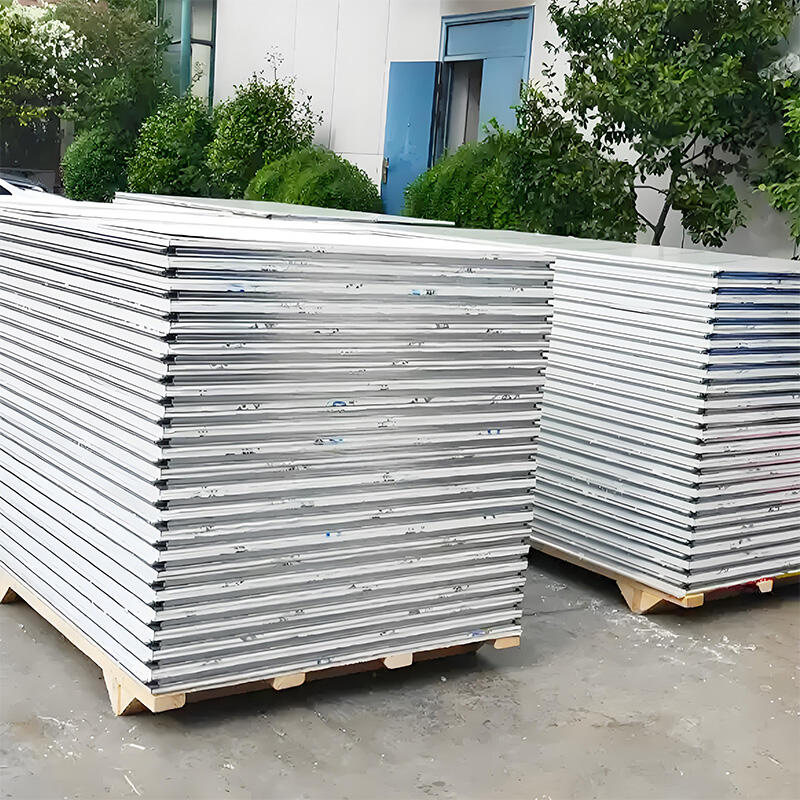

handmade rock wool sandwich panel

Handmade rock wool sandwich panels represent a sophisticated construction solution that combines superior insulation properties with structural integrity. These panels consist of three layers: two high-strength steel facings that sandwich a core of carefully compressed rock wool. The manufacturing process, though handmade, follows precise specifications to ensure consistent quality and performance. The rock wool core, made from natural basalt rock, provides exceptional thermal insulation with R-values typically ranging from 3.5 to 4.0 per inch thickness. These panels excel in fire resistance, maintaining their structural integrity for up to four hours in extreme temperatures, making them ideal for buildings requiring stringent safety standards. The panels feature tongue and groove joints that create an airtight seal when assembled, enhancing their thermal efficiency and weather resistance. Their versatility allows for both vertical and horizontal installation, accommodating various architectural designs and construction requirements. The panels typically range from 50mm to 200mm in thickness, offering flexibility in meeting different insulation demands while maintaining a relatively lightweight profile. Their durability extends beyond thermal properties, offering excellent acoustic insulation and moisture resistance, making them suitable for diverse environmental conditions.