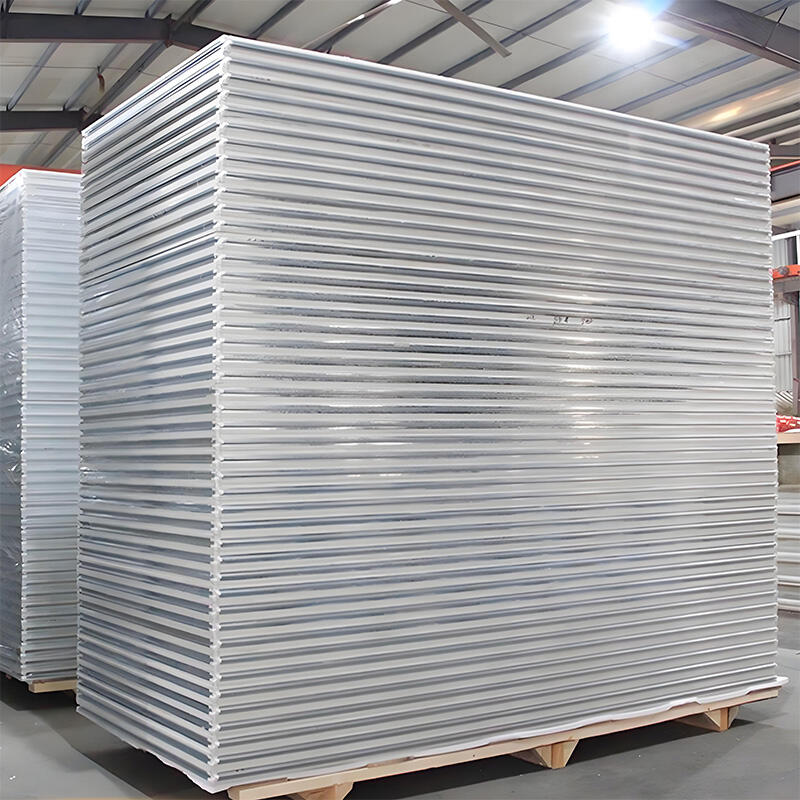

sulfur oxygen magnesium sandwich panel

The sulfur oxygen magnesium sandwich panel represents a groundbreaking advancement in construction materials technology, combining durability, sustainability, and exceptional performance characteristics. This innovative composite material consists of multiple layers strategically engineered to maximize strength while minimizing weight. At its core, the panel utilizes a unique combination of sulfur, oxygen, and magnesium compounds, creating a structure that offers superior thermal insulation properties and remarkable structural integrity. The panel's composition allows for excellent fire resistance, moisture protection, and sound dampening capabilities, making it ideal for various construction applications. The manufacturing process involves precise layering techniques that ensure uniform distribution of materials, resulting in consistent performance across the entire panel surface. These panels have demonstrated exceptional resistance to environmental factors, including UV radiation, extreme temperatures, and chemical exposure, significantly extending their service life compared to traditional building materials. The versatility of sulfur oxygen magnesium sandwich panels makes them suitable for both commercial and residential construction, particularly in areas where thermal efficiency and structural strength are paramount considerations. Their lightweight nature facilitates easier installation and reduces the overall load on building structures, while their composite structure provides enhanced durability and reduced maintenance requirements.