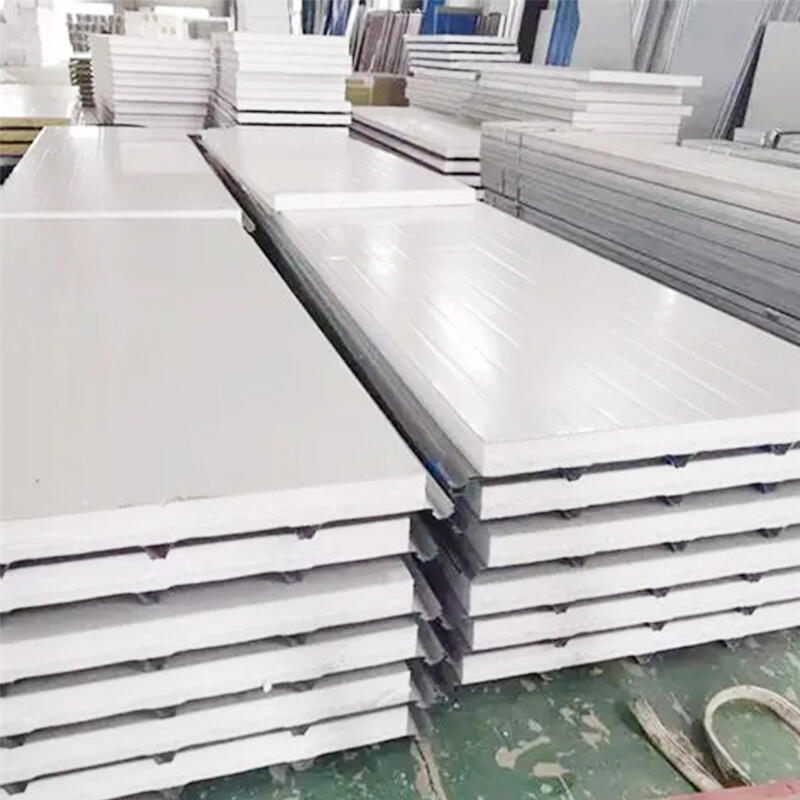

panel sandwich polyurethane

Panel sandwich polyurethane represents a cutting-edge construction material that combines structural integrity with superior insulation properties. These panels consist of two high-strength facing materials bonded to a core of polyurethane foam, creating a robust composite structure that delivers exceptional thermal performance. The panels are manufactured through a continuous production process where liquid polyurethane is injected between the facing materials and expands to form a rigid, closed-cell structure. This advanced construction method results in panels that typically range from 40mm to 200mm in thickness, offering varying degrees of thermal resistance and structural capabilities. The facing materials can include steel, aluminum, or fiber-reinforced polymers, each selected based on specific application requirements. These panels have revolutionized modern construction by offering a complete building envelope solution that addresses thermal efficiency, moisture control, and structural requirements in a single product. Their versatility makes them ideal for various applications, including industrial buildings, cold storage facilities, commercial structures, and residential projects. The panels incorporate tongue-and-groove joining systems that ensure air-tight connections and simplified installation processes, while also maintaining thermal continuity across the entire surface area.