pu insulated panel

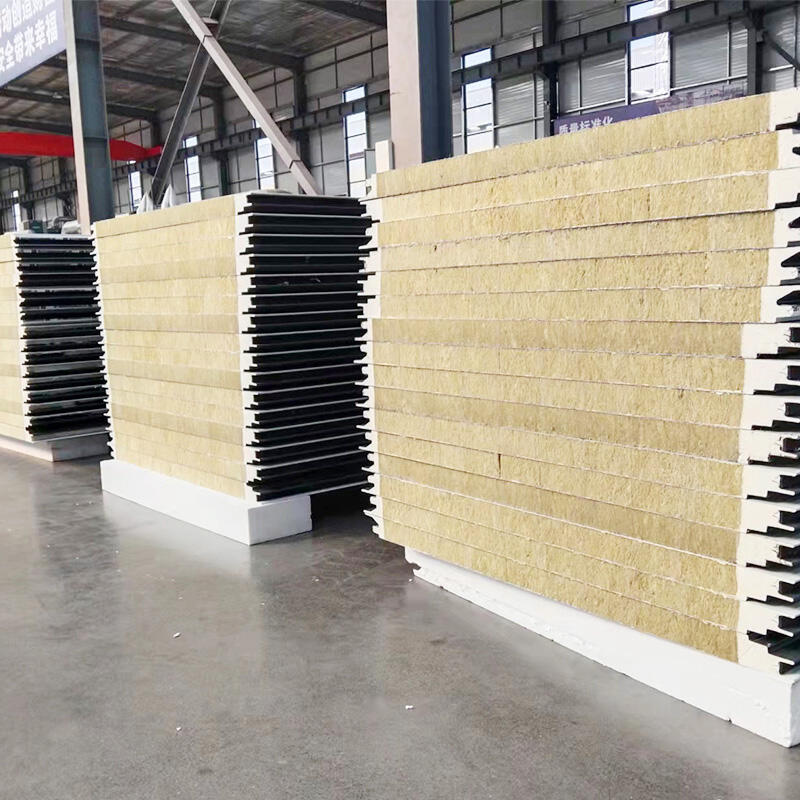

PU insulated panels represent a cutting-edge building material solution that combines superior thermal insulation with structural integrity. These panels consist of a polyurethane foam core sandwiched between two high-strength facing materials, typically steel or aluminum sheets. The polyurethane core provides exceptional thermal resistance with R-values significantly higher than traditional insulation materials, making these panels highly effective in maintaining desired indoor temperatures. The manufacturing process involves injecting liquid polyurethane between the facing materials, which then expands and cures to create a rigid, unified panel structure. These panels are engineered to precise specifications, featuring tongue-and-groove joining systems that ensure airtight connections between adjacent panels. The versatility of PU insulated panels extends across various applications, from cold storage facilities and industrial buildings to commercial structures and residential projects. Their pre-fabricated nature significantly reduces installation time and labor costs while ensuring consistent quality throughout the structure. The panels also demonstrate remarkable durability, resistance to moisture, and structural stability, contributing to their growing popularity in modern construction projects.