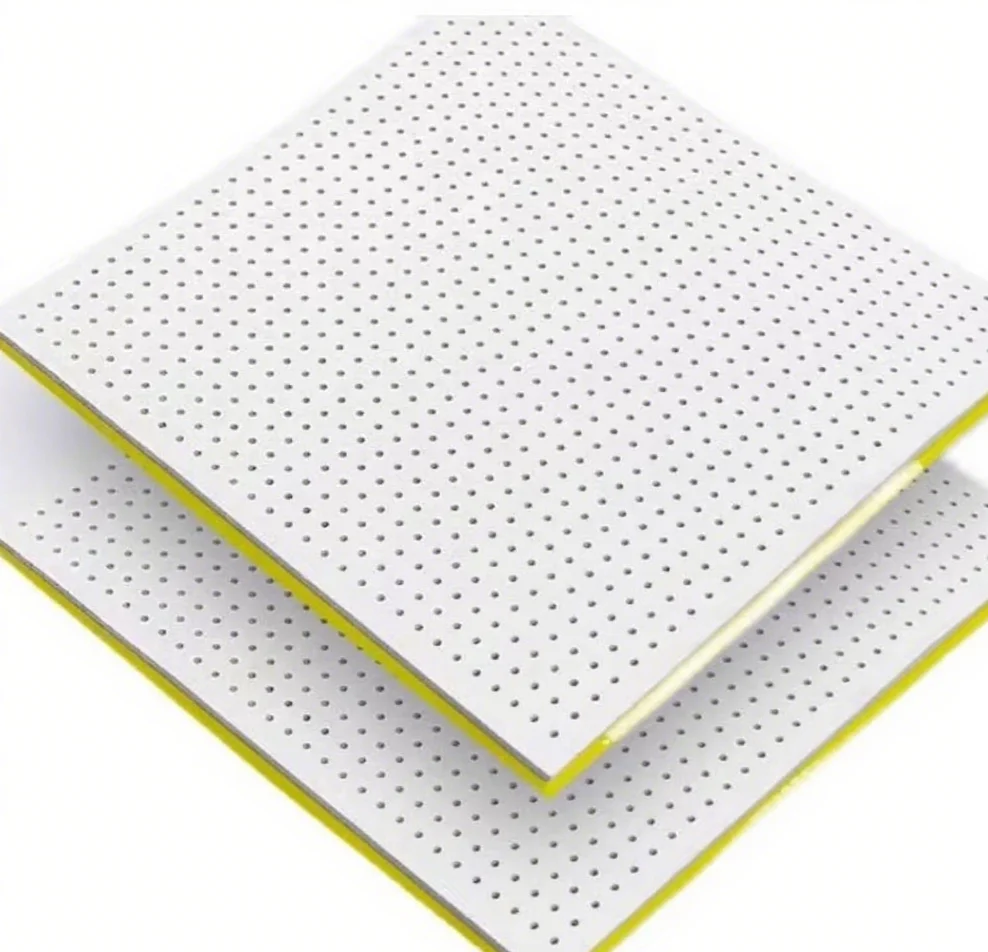

In today's construction industry, environmental sustainability has become a critical consideration for architects, builders, and property developers. As the demand for eco-friendly building materials continues to rise, rock wool sandwich panels have emerged as a compelling solution that combines excellent insulation properties with potential environmental benefits. These composite panels consist of rock wool insulation core sandwiched between two metal sheets, creating a versatile building component that addresses both performance and environmental concerns.

The environmental friendliness of building materials extends beyond their initial production to encompass their entire lifecycle, from raw material extraction to end-of-life disposal. When evaluating the ecological impact of rock wool sandwich panels, multiple factors must be considered including manufacturing processes, energy efficiency contributions, durability, and recyclability. Understanding these aspects provides valuable insights for making informed decisions about sustainable construction practices.

Composition and Manufacturing Process of Rock Wool Sandwich Panels

Raw Material Sources and Extraction

Rock wool, the core component of these sandwich panels, is manufactured primarily from basalt rock and recycled steel slag. Basalt is an abundant volcanic rock that constitutes a significant portion of the Earth's crust, making it a readily available natural resource. The extraction process involves quarrying basalt from volcanic deposits, which generally has a lower environmental impact compared to mining operations for other insulation materials.

Steel slag, a byproduct of steel production, represents approximately 20-30% of the raw material input for rock wool manufacturing. By utilizing this industrial waste stream, rock wool production contributes to circular economy principles by diverting materials that would otherwise require disposal. This recycling aspect significantly reduces the overall environmental footprint of the manufacturing process.

Production Energy Requirements

The manufacturing process of rock wool involves melting the raw materials at temperatures reaching 1500°C, which requires substantial energy input. However, modern production facilities have implemented various energy efficiency measures including heat recovery systems and optimized furnace designs. Many manufacturers have also transitioned to renewable energy sources or implemented carbon offset programs to minimize their environmental impact.

Compared to other insulation materials like polyurethane foam or polystyrene, rock wool production generally has a more favorable carbon footprint when considering the entire manufacturing cycle. The longevity and performance characteristics of rock wool sandwich panels help offset the initial energy investment through decades of energy-saving performance in buildings.

Environmental Benefits During Building Operation

Thermal Insulation Performance

The exceptional thermal insulation properties of rock wool sandwich panels contribute significantly to building energy efficiency. With thermal conductivity values typically ranging from 0.035 to 0.040 W/mK, these panels effectively minimize heat transfer through building envelopes. This superior insulation performance directly translates to reduced energy consumption for heating and cooling systems throughout the building's operational life.

Studies have demonstrated that well-insulated buildings using rock wool sandwich panels can achieve energy savings of 30-50% compared to structures with conventional insulation systems. Over a building's typical 50-year lifespan, these energy savings result in substantial reductions in greenhouse gas emissions, far outweighing the environmental costs associated with panel production and installation.

Indoor Air Quality Contributions

Rock wool sandwich panels contribute to healthier indoor environments through their non-combustible nature and absence of volatile organic compounds (VOCs). Unlike some synthetic insulation materials, rock wool does not emit harmful chemicals or degrade over time to produce indoor air pollutants. This characteristic supports sustainable building practices by maintaining healthy indoor environments without compromising air quality.

The breathable nature of rock wool allows moisture vapor transmission while preventing condensation buildup within wall systems. This moisture management capability helps prevent mold growth and maintains structural integrity, extending building lifespan and reducing the need for premature renovation or replacement activities.

Durability and Lifecycle Considerations

Long-term Performance Characteristics

The durability of rock wool sandwich panels represents a crucial environmental advantage, as longer-lasting building components reduce the frequency of replacement and associated environmental impacts. Rock wool maintains its insulation properties for decades without significant degradation, unlike some organic materials that may compress or lose effectiveness over time.

Fire resistance is another key durability factor, as rock wool sandwich panels can withstand temperatures exceeding 1000°C without combustion. This fire-resistant property not only enhances building safety but also contributes to environmental protection by reducing the risk of catastrophic fires that could result in significant material waste and reconstruction requirements.

Maintenance Requirements

Rock wool sandwich panels typically require minimal maintenance throughout their service life, which reduces the environmental impact associated with ongoing building upkeep. The non-organic nature of rock wool prevents pest infestation and biological degradation, eliminating the need for chemical treatments or frequent replacements that other materials might require.

The corrosion-resistant coatings applied to the metal facings of sandwich panels further extend their lifespan and reduce maintenance needs. When properly specified and installed, these panels can provide decades of reliable performance with minimal intervention, supporting sustainable building operations through reduced resource consumption and waste generation.

End-of-Life Management and Recycling Potential

Material Recovery Options

At the end of their service life, rock wool sandwich panels offer several recycling and recovery options that support circular economy principles. The metal facings, typically made from steel or aluminum, can be easily separated and recycled through established metal recycling infrastructure. These metals retain their properties through multiple recycling cycles, providing valuable raw materials for new products.

The rock wool core material can also be recycled, though the process requires specialized facilities. Recycled rock wool can be reprocessed into new insulation products or used as aggregate in other applications. Some manufacturers have established take-back programs that facilitate the collection and recycling of their products, further enhancing the environmental credentials of rock wool sandwich panels.

Disposal Considerations

When recycling options are not available, rock wool sandwich panels can be disposed of safely without significant environmental harm. Rock wool is chemically inert and does not leach harmful substances into soil or groundwater, making it suitable for landfill disposal when necessary. However, the preference should always be for material recovery and recycling to maximize resource efficiency.

The separation of components during demolition can be facilitated through proper design and installation practices that avoid permanent bonding between different materials. This design consideration supports end-of-life material recovery and reflects the growing emphasis on designing for disassembly in sustainable construction practices.

Comparative Environmental Assessment

Lifecycle Analysis Results

Comprehensive lifecycle assessments of rock wool sandwich panels consistently demonstrate favorable environmental performance compared to many alternative building systems. These studies evaluate environmental impacts across multiple categories including global warming potential, acidification potential, and resource depletion, providing a holistic view of environmental performance.

When compared to traditional brick and mortar construction or other insulated panel systems, rock wool sandwich panels typically show lower overall environmental impacts due to their excellent thermal performance, durability, and potential for recycling. The reduced construction time and waste generation during installation also contribute to their favorable environmental profile.

Carbon Footprint Analysis

The carbon footprint of rock wool sandwich panels includes both embodied carbon from manufacturing and operational carbon savings from improved building energy efficiency. While the initial embodied carbon may be higher than some alternatives due to the high-temperature manufacturing process, the operational energy savings typically result in carbon neutrality within 1-3 years of building operation.

Over a typical building lifespan, the net carbon benefit of using rock wool sandwich panels can be substantial, particularly in climate zones where heating and cooling loads are significant. This favorable carbon profile supports building certification programs such as LEED, BREEAM, and other green building standards that prioritize energy efficiency and environmental performance.

Industry Certifications and Standards

Environmental Certifications

Many rock wool sandwich panel manufacturers have obtained environmental certifications that validate their sustainability claims and manufacturing practices. Environmental Product Declarations (EPDs) provide transparent information about environmental impacts based on standardized lifecycle assessment methodologies, enabling informed product selection for sustainable construction projects.

Certifications such as GREENGUARD and similar indoor air quality standards confirm that rock wool sandwich panels do not contribute to indoor air pollution, supporting healthy building environments. These third-party certifications provide independent verification of environmental and health claims, adding credibility to sustainability assertions.

Compliance with Green Building Standards

Rock wool sandwich panels can contribute to various green building certification programs through their energy performance, material selection criteria, and indoor environmental quality characteristics. The high insulation values help buildings achieve energy efficiency targets, while the use of recycled content in manufacturing supports material resource efficiency requirements.

Many green building standards also recognize the importance of material durability and lifecycle thinking, areas where rock wool sandwich panels perform well. The fire safety characteristics and low maintenance requirements further support sustainable building operations and occupant safety objectives promoted by these standards.

FAQ

Do rock wool sandwich panels contain any harmful chemicals?

Rock wool sandwich panels are manufactured from natural volcanic rock and recycled steel slag, containing no harmful chemicals or volatile organic compounds. The inorganic nature of rock wool means it does not off-gas or deteriorate to produce indoor air pollutants, making it safe for use in residential and commercial buildings. The panels meet strict indoor air quality standards and contribute to healthy building environments.

How much energy do rock wool sandwich panels save compared to conventional construction?

Buildings constructed with rock wool sandwich panels typically achieve 30-50% energy savings compared to conventional construction methods. The exceptional thermal insulation properties, with thermal conductivity values of 0.035-0.040 W/mK, significantly reduce heating and cooling energy requirements. Over a building's operational life, these energy savings far exceed the environmental costs of panel production, typically achieving carbon neutrality within 1-3 years.

Can rock wool sandwich panels be recycled at the end of their useful life?

Yes, rock wool sandwich panels offer excellent recycling potential at the end of their service life. The metal facings can be easily separated and recycled through standard metal recycling processes, retaining their properties through multiple cycles. The rock wool core can also be recycled through specialized facilities or used as aggregate in other applications. Many manufacturers offer take-back programs to facilitate proper recycling and material recovery.

How long do rock wool sandwich panels typically last in building applications?

Rock wool sandwich panels are designed for long-term performance, typically lasting 50 years or more in building applications. The inorganic nature of rock wool prevents biological degradation, while the fire-resistant properties protect against thermal damage. The durability extends to maintaining insulation performance over decades without compression or degradation, supported by corrosion-resistant coatings on metal facings that minimize maintenance requirements throughout the service life.

Table of Contents

- Composition and Manufacturing Process of Rock Wool Sandwich Panels

- Environmental Benefits During Building Operation

- Durability and Lifecycle Considerations

- End-of-Life Management and Recycling Potential

- Comparative Environmental Assessment

- Industry Certifications and Standards

-

FAQ

- Do rock wool sandwich panels contain any harmful chemicals?

- How much energy do rock wool sandwich panels save compared to conventional construction?

- Can rock wool sandwich panels be recycled at the end of their useful life?

- How long do rock wool sandwich panels typically last in building applications?