Choosing the right EPS sandwich panel for your construction project requires careful consideration of multiple factors that directly impact performance, durability, and cost-effectiveness. These innovative building materials have revolutionized modern construction by offering superior insulation properties, structural integrity, and installation efficiency. Understanding the various types available and their specific applications helps ensure optimal results for residential, commercial, and industrial buildings.

Understanding EPS Sandwich Panel Construction and Materials

Core Material Properties and Performance

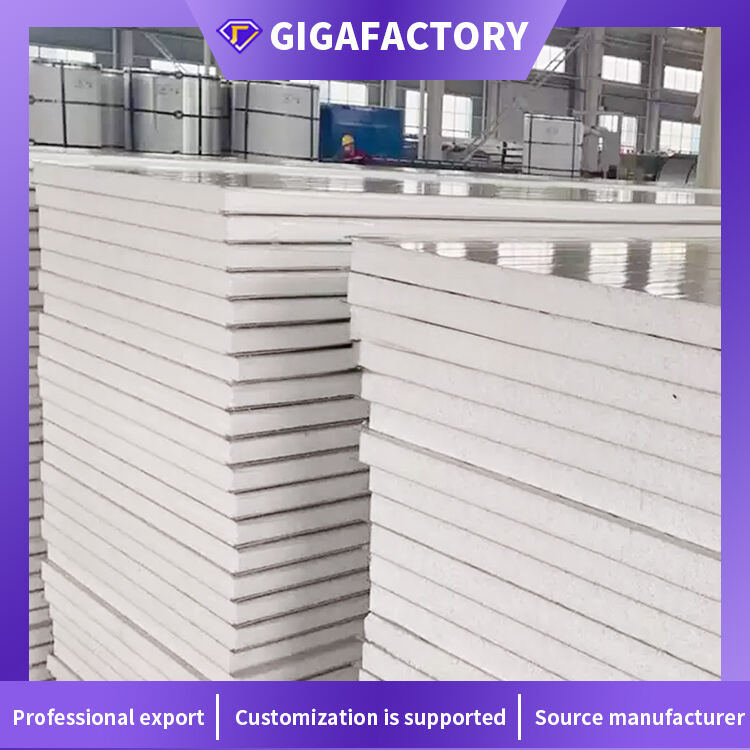

The expanded polystyrene core forms the heart of every EPS sandwich panel system, providing exceptional thermal insulation while maintaining structural stability. This lightweight yet robust material exhibits excellent compressive strength, making it ideal for load-bearing applications in various construction scenarios. The cellular structure of EPS creates countless air pockets that effectively resist heat transfer, resulting in superior energy efficiency for buildings.

Manufacturing processes significantly influence the final quality and performance characteristics of the core material. High-quality EPS cores undergo controlled expansion and molding procedures that ensure uniform density distribution throughout the panel thickness. This consistency directly affects thermal performance, structural integrity, and long-term durability under varying environmental conditions.

Face Sheet Materials and Configurations

Face sheets protect the EPS core while contributing to the panel's overall structural performance and aesthetic appeal. Common materials include galvanized steel, aluminum, stainless steel, and fiber cement, each offering distinct advantages for specific applications. Steel face sheets provide excellent durability and fire resistance, while aluminum options offer superior corrosion resistance in coastal or industrial environments.

Surface treatments and coatings further enhance face sheet performance by providing additional protection against weathering, UV radiation, and chemical exposure. Polyester, PVDF, and plastisol coatings extend service life while offering diverse color options and finish textures. The selection of appropriate face sheet materials and treatments depends on project requirements, environmental conditions, and aesthetic preferences.

Technical Specifications and Performance Standards

Thermal Insulation Requirements

Thermal performance represents one of the most critical factors when selecting an EPS sandwich panel system for any construction project. The R-value or thermal resistance directly correlates with panel thickness and EPS core density, affecting heating and cooling costs throughout the building's operational life. Standard panel thicknesses range from 50mm to 250mm, with higher thicknesses providing superior insulation properties.

Climate zone requirements influence the minimum thermal performance standards that panels must meet to comply with local building codes and energy efficiency regulations. Cold climates demand higher R-values to prevent heat loss, while hot climates focus on preventing heat gain and maintaining indoor comfort levels. Understanding these regional requirements ensures proper panel selection and optimal energy performance.

Structural Load Capacity

Load-bearing capacity determines the maximum spans and structural applications suitable for different EPS sandwich panel configurations. Panel thickness, face sheet gauge, and core density collectively influence structural performance under various loading conditions including dead loads, live loads, wind loads, and seismic forces. Engineering calculations verify that selected panels meet or exceed project-specific structural requirements.

Span tables provided by manufacturers offer quick reference guides for determining maximum allowable spans under different loading scenarios. These tables consider factors such as deflection limits, stress concentrations, and safety factors to ensure reliable structural performance. Professional structural analysis may be required for complex applications or non-standard loading conditions.

Application-Specific Selection Criteria

Wall Panel Applications

Wall panel selection depends on building type, height restrictions, wind exposure, and thermal requirements specific to the geographic location and intended use. Residential applications typically require panels with moderate structural capacity and excellent thermal performance, while commercial and industrial buildings may prioritize fire resistance and structural strength over other factors.

Installation methods influence panel selection, with some systems designed for horizontal installation while others accommodate vertical orientation. Connection details, sealing systems, and compatibility with existing structural elements affect the overall system performance and weather resistance. Proper panel selection ensures seamless integration with architectural design requirements and construction schedules.

Roof Panel Considerations

Roof applications demand enhanced structural performance to resist snow loads, wind uplift forces, and thermal cycling effects that can cause expansion and contraction. Panel profiles and connection systems must accommodate these dynamic forces while maintaining weather-tight seals throughout the service life. Slope requirements and drainage considerations influence panel selection and installation details.

Thermal bridging prevention becomes particularly important in roof applications where temperature differentials can be substantial. Advanced panel designs incorporate thermal breaks and continuous insulation strategies that minimize heat transfer through structural connections. These features contribute to overall building energy efficiency and occupant comfort.

Quality Assessment and Certification Standards

Manufacturing Quality Control

Manufacturing standards and quality control procedures significantly impact panel performance and reliability throughout the building's service life. Reputable manufacturers implement comprehensive testing protocols that verify thermal performance, structural capacity, fire resistance, and durability under accelerated aging conditions. These quality assurance measures ensure consistent product performance and compliance with industry standards.

Third-party certification programs provide independent verification of manufacturer claims and product performance characteristics. Organizations such as FM Global, UL, and ICC-ES evaluate panels according to rigorous testing protocols that simulate real-world conditions and extreme events. Certified products offer greater confidence in long-term performance and may be required for certain project types or insurance considerations.

Industry Standards and Code Compliance

Building codes and industry standards establish minimum performance requirements for EPS sandwich panel systems used in various applications. These regulations address fire safety, structural adequacy, energy efficiency, and environmental considerations that protect public health and safety. Compliance with applicable codes ensures legal conformity and may affect project approval and occupancy permits.

International standards such as ASTM, ISO, and EN specifications provide standardized testing methods and performance criteria that enable accurate comparison between different panel products and manufacturers. Understanding these standards helps specifiers make informed decisions based on verified performance data rather than marketing claims alone.

Installation and Long-Term Considerations

Installation Requirements and Compatibility

Installation complexity and compatibility with existing construction methods influence panel selection decisions, particularly for renovation projects or specialized applications. Some panel systems require specific fastening methods, structural supports, or sealing procedures that may affect construction schedules and labor costs. Early consideration of installation requirements prevents costly delays and ensures proper system performance.

Contractor experience and training requirements vary between different panel systems and manufacturers. Complex installation procedures may require specialized training or certification programs that ensure proper installation techniques and warranty compliance. Simple, contractor-friendly systems often provide better value through reduced installation time and lower labor costs.

Maintenance and Service Life Expectations

Long-term maintenance requirements and expected service life directly impact the total cost of ownership for EPS sandwich panel systems. High-quality panels with appropriate protective coatings and proper installation typically require minimal maintenance while providing decades of reliable service. Regular inspection schedules and preventive maintenance procedures help identify potential issues before they compromise system performance.

Environmental factors such as industrial pollution, salt air exposure, and extreme temperature cycles affect panel degradation rates and maintenance intervals. Understanding local environmental conditions helps predict maintenance needs and select appropriate panel specifications that optimize long-term performance and cost-effectiveness.

FAQ

What thickness of EPS sandwich panel should I choose for my climate zone

The appropriate panel thickness depends on your specific climate zone and local energy codes. Cold climates typically require 100-200mm thick panels to achieve adequate R-values, while moderate climates may perform well with 75-100mm panels. Consult local building codes and energy efficiency requirements to determine minimum thickness standards for your area.

How do I determine the structural capacity needed for my application

Structural capacity requirements depend on span length, loading conditions, and safety factors specified by local building codes. Review manufacturer span tables and consult with a structural engineer for applications involving heavy loads, long spans, or unusual conditions. Wind and seismic loads may also influence structural requirements in certain geographic areas.

What certifications should I look for when selecting EPS sandwich panels

Look for third-party certifications from recognized organizations such as FM Global for fire performance, UL listings for safety standards, and ICC-ES reports for code compliance. Energy performance certifications and environmental product declarations provide additional verification of manufacturer claims. These certifications ensure products meet industry standards and regulatory requirements.

Can EPS sandwich panels be used in high-temperature or fire-rated applications

Standard EPS panels have temperature limitations and may not be suitable for high-temperature applications without special considerations. Fire-rated assemblies require specific panel constructions, installation details, and may need additional fire-resistant materials. Consult manufacturer specifications and fire safety engineers for applications requiring enhanced fire performance or high-temperature resistance.