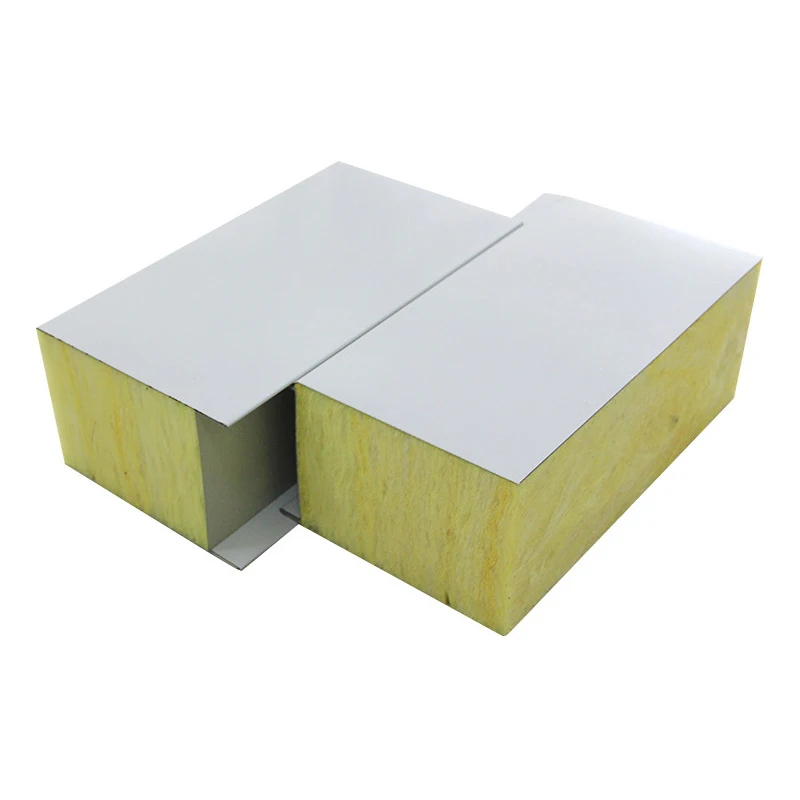

This premium 120mm phenolic aldehyde sandwich panel delivers superior fire resistance and thermal insulation for high-rise building applications. Engineered with an A-grade fire rating, these wall panels provide outstanding protection against flame spread and smoke development. The robust phenolic aldehyde core is securely bonded between high-strength facing materials, creating a durable and lightweight composite structure. Perfect for modern commercial and residential towers, these panels offer excellent dimensional stability and weather resistance while meeting stringent building safety codes. The precision-manufactured panels install efficiently and create a seamless appearance. With exceptional structural integrity and proven fire-resistant properties, these sandwich panels are an ideal choice for architects and contractors seeking reliable wall solutions for tall building projects where safety and performance are paramount.

Name |

Phenolic Aldehyde Sandwich Panel |

Effective width |

Wall panel: 950mm 1150mm |

Length |

customized |

materials |

Phenolic Aldehyde core material, Color steel sheet |

Structure |

Upper and lower layer: Color steel sheet Middle: PU core material |

Thickness |

Color steel sheet: 0.3-1.2mm Phenolic Aldehyde foam: 50mm 75mm 100mm 150mm 200mm |

The EPS density |

35-55kg/m3 |

Steel sheet color |

Ivory white, off white , sea blue, sky blue, lotus green, Grey brick, marble and wooden grain, bright red, etc… |

lifetime |

15~20 years |

Character |

Light in weight, heat & sound insulation, fire proof, green and environmental protection |

Application |

various roofs and walls referring to the large size factory buildings, storage, exhibition halls, gymnasiums ,Purifying factory, combined house, etc. |

Advantage Category |

Specific Description |

Thermal Insulation |

Core materials (such as rock wool, polystyrene, etc.) have low thermal conductivity, which can effectively block heat transfer and meet the temperature control needs of different climatic regions. |

Fire Resistance |

Some core materials (such as rock wool, glass wool) are non-combustible. Combined with the fire-resistant coating of color steel plates, they can delay the spread of fire and improve the fire safety level of buildings. |

Structural Strength and Durability |

The outer color steel plates have high strength, and the sandwich structure has good toughness, which can bear a certain load and impact, is not easy to deform, and has a service life of more than 10-20 years. |

Construction Convenience |

Lightweight (about 10-30kg/m²), with low requirements on the load-bearing capacity of building foundations; factory-produced standardized products, on-site splicing and installation, significantly shortening the construction period. |

Aesthetics and Maintainability |

The surface has various color coatings, with a neat appearance that does not require additional decoration; the coating is acid and alkali resistant, corrosion resistant, and UV resistant, and daily maintenance only requires regular cleaning with low cost. |

Sound Absorption and Noise Reduction |

Porous core materials such as glass wool can absorb sound waves, reduce noise transmission, and improve the internal acoustic environment of buildings (such as schools, hospitals, etc.). |

Wide Applicability |

Core materials and thickness can be flexibly selected according to needs, meeting the functional requirements of various building scenarios such as industrial workshops, residences, cold storage, and prefabricated houses. |

Energy-Saving Insulated Phenolic Aldehyde Sandwich Panel Roofing 0.6 mm PPGI for Cold Chain Warehouse

High Quality Tiny Luxury Prefabricated House with Waterproof Features for Living Bathroom Kitchen for Tourist Attractions

Factory Direct 75 mm Glass Wool Sandwich Panel Thermal Roof Board for Cold Storage Warehouse

2025 Hot Sale Space-Saving Container House Foldable Office for Construction Site