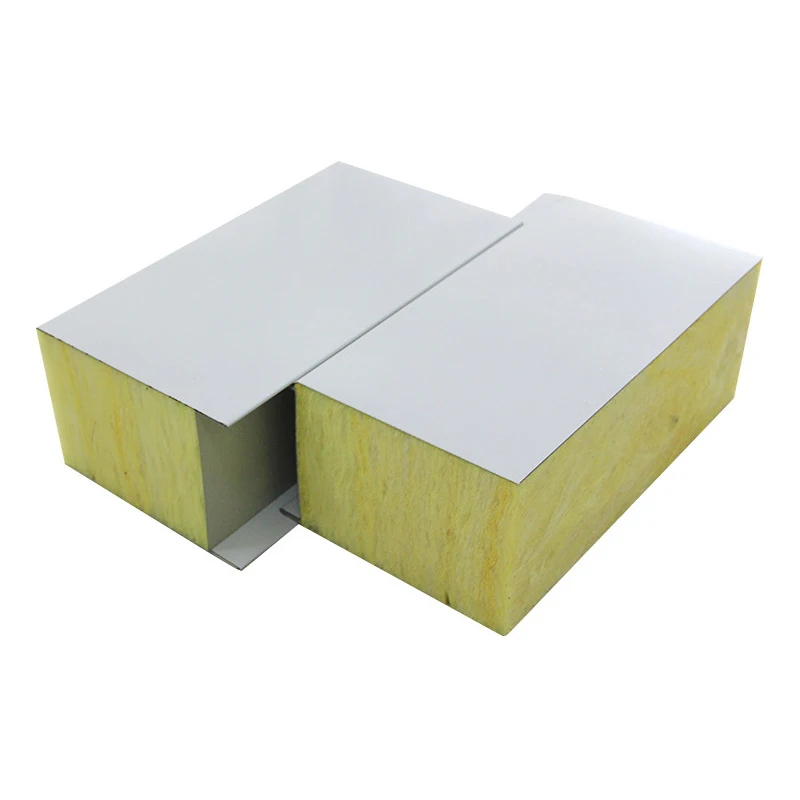

The 75mm polyurethane sandwich panel wall system delivers superior hygiene and insulation performance ideal for food processing facilities. Featuring food-grade stainless steel facing on both sides, these panels create a seamless, easy-to-clean surface that prevents bacterial growth and meets strict sanitation requirements. The dense polyurethane core provides excellent thermal insulation while maintaining structural integrity. With a thickness of 75mm, these panels offer optimal temperature control and energy efficiency for food production environments. The tongue-and-groove joining system ensures airtight installation and prevents thermal bridges. Highly resistant to chemicals, moisture, and impact, these panels are perfect for meat processing plants, dairy facilities, and other food-grade operations where maintaining controlled environments and strict hygiene standards is crucial. Installation is quick and straightforward, reducing construction time and costs.

Product Model |

Polyurethane Sandwich Panel/PU Sandwich Panel |

Product Category |

1150. |

Product thickness |

50mm 75mm 100mm 125mm 150mm. |

Product colour |

White grey, high-gloss white, snowflake white, ivory white, fruit blue, fruit green, silver grey, orange yellow. |

Product parameters |

Limited width of 1.15 metres, length customised according to customer requirements; conventional thickness of 50mm steel 0.426mm weight 35k: the weight of the product per square metre is 7.5kg, both sides of the case of adding a steel belt, the uniform cloth load-bearing capacity of 150kg / square. |

Advantage of structure |

Enterprise-type splicing quick installation. |

Product characteristics |

Polyurethane sandwich panels are recognised as the best material for thermal insulation in the world today.Light weight, good thermal insulation, good overall steel, high bearing capacity. |

Advantage Category |

Specific Description |

Thermal Insulation |

Core materials (such as rock wool, polystyrene, etc.) have low thermal conductivity, which can effectively block heat transfer and meet the temperature control needs of different climatic regions. |

Fire Resistance |

Some core materials (such as rock wool, glass wool) are non-combustible. Combined with the fire-resistant coating of color steel plates, they can delay the spread of fire and improve the fire safety level of buildings. |

Structural Strength and Durability |

The outer color steel plates have high strength, and the sandwich structure has good toughness, which can bear a certain load and impact, is not easy to deform, and has a service life of more than 10-20 years. |

Construction Convenience |

Lightweight (about 10-30kg/m²), with low requirements on the load-bearing capacity of building foundations; factory-produced standardized products, on-site splicing and installation, significantly shortening the construction period. |

Aesthetics and Maintainability |

The surface has various color coatings, with a neat appearance that does not require additional decoration; the coating is acid and alkali resistant, corrosion resistant, and UV resistant, and daily maintenance only requires regular cleaning with low cost. |

Sound Absorption and Noise Reduction |

Porous core materials such as glass wool can absorb sound waves, reduce noise transmission, and improve the internal acoustic environment of buildings (such as schools, hospitals, etc.). |

Wide Applicability |

Core materials and thickness can be flexibly selected according to needs, meeting the functional requirements of various building scenarios such as industrial workshops, residences, cold storage, and prefabricated houses. |

Energy-Saving Insulated Phenolic Aldehyde Sandwich Panel Roofing 0.6 mm PPGI for Cold Chain Warehouse

High Quality Tiny Luxury Prefabricated House with Waterproof Features for Living Bathroom Kitchen for Tourist Attractions

Factory Direct 75 mm Glass Wool Sandwich Panel Thermal Roof Board for Cold Storage Warehouse

2025 Hot Sale Space-Saving Container House Foldable Office for Construction Site