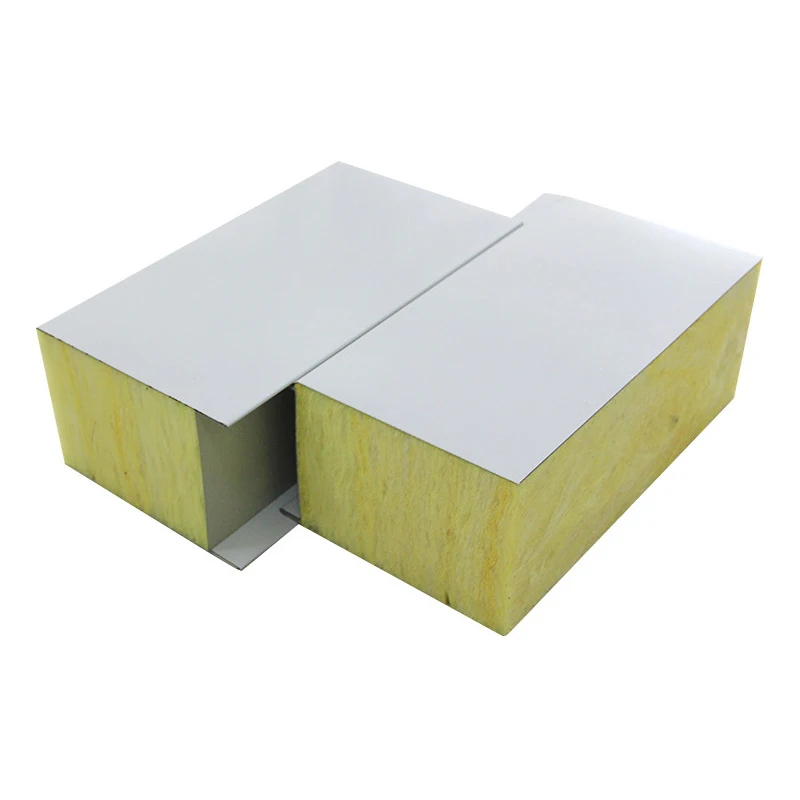

The high-performance phenolic sandwich panel offers superior impact resistance and durability, making it an ideal choice for educational facility construction. Engineered specifically for school and university buildings, these panels feature a robust phenolic core sandwiched between protective outer layers, creating a sturdy composite that withstands daily wear and tear. The panels excel in high-traffic areas, providing excellent resistance to scratches, dents, and impacts while maintaining their aesthetic appeal. Fire-resistant and moisture-proof properties ensure enhanced safety and longevity in educational environments. Easy to install and maintain, these panels offer excellent thermal insulation and sound dampening capabilities, creating comfortable learning spaces. Their versatile design allows for seamless integration into various architectural styles, while the smooth surface enables easy cleaning and sanitization. Choose these reliable phenolic sandwich panels for a long-lasting, safe, and visually appealing building solution that meets the demanding requirements of modern educational facilities.

Name |

Phenolic Aldehyde Sandwich Panel |

Effective width |

Wall panel: 950mm 1150mm |

Length |

customized |

materials |

Phenolic Aldehyde core material, Color steel sheet |

Structure |

Upper and lower layer: Color steel sheet Middle: PU core material |

Thickness |

Color steel sheet: 0.3-1.2mm Phenolic Aldehyde foam: 50mm 75mm 100mm 150mm 200mm |

The EPS density |

35-55kg/m3 |

Steel sheet color |

Ivory white, off white , sea blue, sky blue, lotus green, Grey brick, marble and wooden grain, bright red, etc… |

lifetime |

15~20 years |

Character |

Light in weight, heat & sound insulation, fire proof, green and environmental protection |

Application |

various roofs and walls referring to the large size factory buildings, storage, exhibition halls, gymnasiums ,Purifying factory, combined house, etc. |

Advantage Category |

Specific Description |

Thermal Insulation |

Core materials (such as rock wool, polystyrene, etc.) have low thermal conductivity, which can effectively block heat transfer and meet the temperature control needs of different climatic regions. |

Fire Resistance |

Some core materials (such as rock wool, glass wool) are non-combustible. Combined with the fire-resistant coating of color steel plates, they can delay the spread of fire and improve the fire safety level of buildings. |

Structural Strength and Durability |

The outer color steel plates have high strength, and the sandwich structure has good toughness, which can bear a certain load and impact, is not easy to deform, and has a service life of more than 10-20 years. |

Construction Convenience |

Lightweight (about 10-30kg/m²), with low requirements on the load-bearing capacity of building foundations; factory-produced standardized products, on-site splicing and installation, significantly shortening the construction period. |

Aesthetics and Maintainability |

The surface has various color coatings, with a neat appearance that does not require additional decoration; the coating is acid and alkali resistant, corrosion resistant, and UV resistant, and daily maintenance only requires regular cleaning with low cost. |

Sound Absorption and Noise Reduction |

Porous core materials such as glass wool can absorb sound waves, reduce noise transmission, and improve the internal acoustic environment of buildings (such as schools, hospitals, etc.). |

Wide Applicability |

Core materials and thickness can be flexibly selected according to needs, meeting the functional requirements of various building scenarios such as industrial workshops, residences, cold storage, and prefabricated houses. |

Energy-Saving Insulated Phenolic Aldehyde Sandwich Panel Roofing 0.6 mm PPGI for Cold Chain Warehouse

High Quality Tiny Luxury Prefabricated House with Waterproof Features for Living Bathroom Kitchen for Tourist Attractions

Factory Direct 75 mm Glass Wool Sandwich Panel Thermal Roof Board for Cold Storage Warehouse

2025 Hot Sale Space-Saving Container House Foldable Office for Construction Site