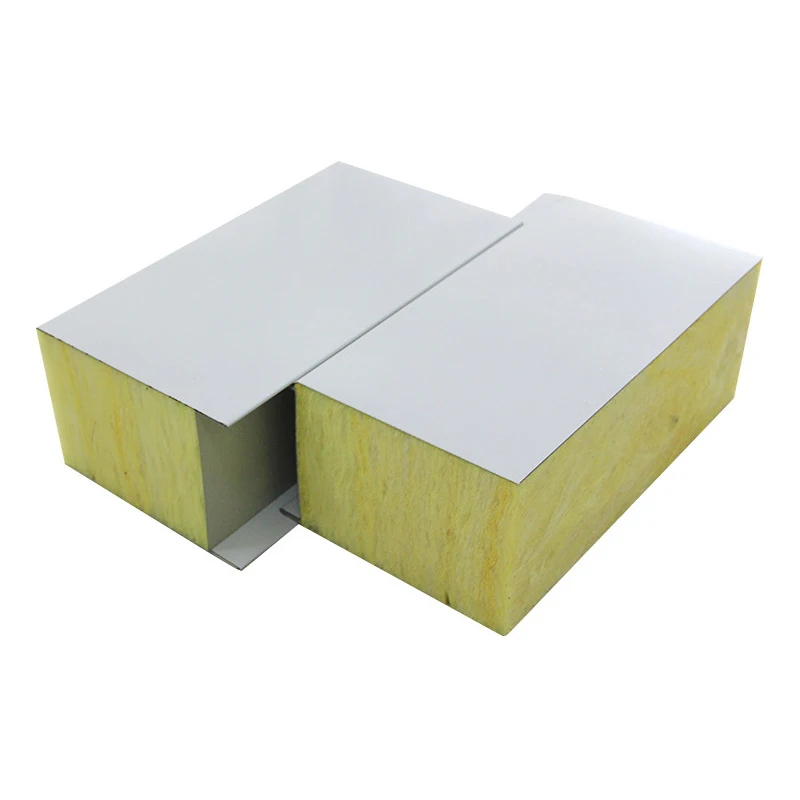

Our advanced modified EPS sandwich panels offer the perfect solution for cleanroom construction, combining superior moisture resistance with exceptional lightweight properties. These custom-colored panels feature a high-quality expanded polystyrene core sandwiched between durable facing materials, providing excellent thermal insulation and structural stability. The panels' moisture-proof design effectively prevents water penetration and mold growth, making them ideal for maintaining strict cleanroom environmental standards. Easy to install and maintain, these panels create seamless, hygienic surfaces essential for pharmaceutical, medical, and electronic manufacturing facilities. Their customizable color options allow for aesthetic flexibility while meeting stringent cleanroom requirements. The lightweight nature of our EPS panels reduces installation time and structural load, offering a cost-effective solution without compromising on performance or durability.

Product Model |

Modified EPS sandwich panel |

Product Category |

1150. |

Product thickness |

50mm 75mm 100mm 125mm 150mm |

Product colour |

White grey, high-gloss white, snowflake white, ivory white, fruit blue, fruit green, silver grey, orange yellow. |

Core Density |

20K, 25K |

Product parameters |

Limited width of 1.15 metres, length customised according to customer requirements; conventional thickness of 50mm steel 0.426mm weight 25k: the weight of the product per square metre is 7kg, both sides of the case of adding a steel belt, uniform load-bearing capacity of 80kg / square. |

Advantage of structure |

Enterprise-type splicing, quick installation. |

Product characteristics |

Currently the most popular domestic fireproof foam, light weight, easy to install, high bearing capacity, overall rigidity, heat insulation, low water absorption, environmentally friendly materials, is currently being promoted in large areas. |

Advantage Category |

Specific Description |

Thermal Insulation |

Core materials (such as rock wool, polystyrene, etc.) have low thermal conductivity, which can effectively block heat transfer and meet the temperature control needs of different climatic regions. |

Fire Resistance |

Some core materials (such as rock wool, glass wool) are non-combustible. Combined with the fire-resistant coating of color steel plates, they can delay the spread of fire and improve the fire safety level of buildings. |

Structural Strength and Durability |

The outer color steel plates have high strength, and the sandwich structure has good toughness, which can bear a certain load and impact, is not easy to deform, and has a service life of more than 10-20 years. |

Construction Convenience |

Lightweight (about 10-30kg/m²), with low requirements on the load-bearing capacity of building foundations; factory-produced standardized products, on-site splicing and installation, significantly shortening the construction period. |

Aesthetics and Maintainability |

The surface has various color coatings, with a neat appearance that does not require additional decoration; the coating is acid and alkali resistant, corrosion resistant, and UV resistant, and daily maintenance only requires regular cleaning with low cost. |

Sound Absorption and Noise Reduction |

Porous core materials such as glass wool can absorb sound waves, reduce noise transmission, and improve the internal acoustic environment of buildings (such as schools, hospitals, etc.). |

Wide Applicability |

Core materials and thickness can be flexibly selected according to needs, meeting the functional requirements of various building scenarios such as industrial workshops, residences, cold storage, and prefabricated houses. |

Energy-Saving Insulated Phenolic Aldehyde Sandwich Panel Roofing 0.6 mm PPGI for Cold Chain Warehouse

High Quality Tiny Luxury Prefabricated House with Waterproof Features for Living Bathroom Kitchen for Tourist Attractions

Factory Direct 75 mm Glass Wool Sandwich Panel Thermal Roof Board for Cold Storage Warehouse

2025 Hot Sale Space-Saving Container House Foldable Office for Construction Site