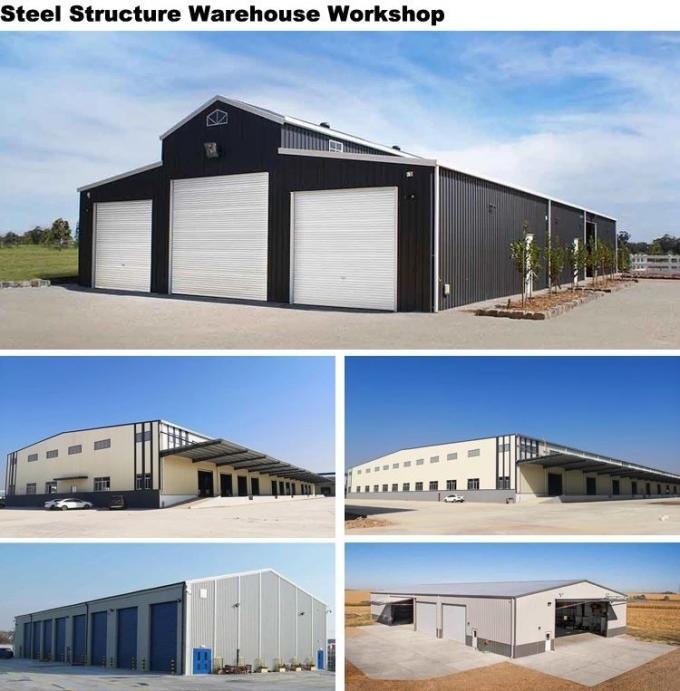

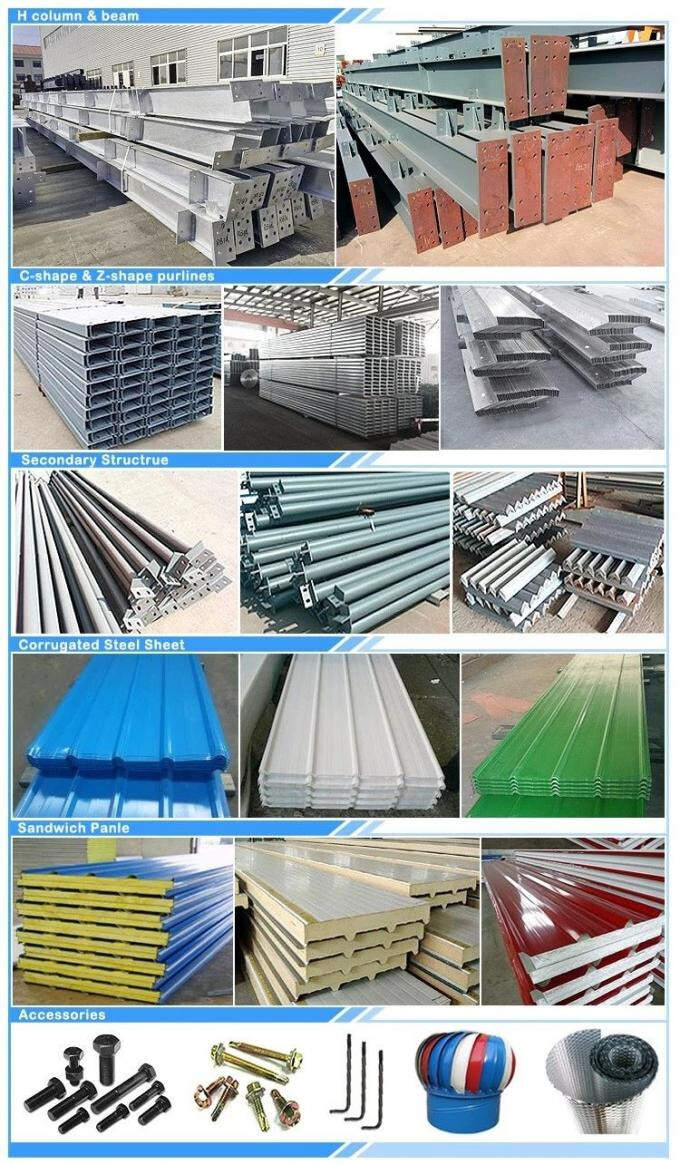

Steel structure warehouses are renowned for their remarkable fire resistance and robust corrosion resistance, making them a preferred choice for various industrial and commercial applications. By definition, a steel structure warehouse primarily consists of steel components that serve as the main load-bearing elements, including steel columns, beams, structural frameworks, and roof trusses. These components are meticulously connected through welding, bolting, or riveting techniques, ensuring a sturdy and reliable structural integrity.

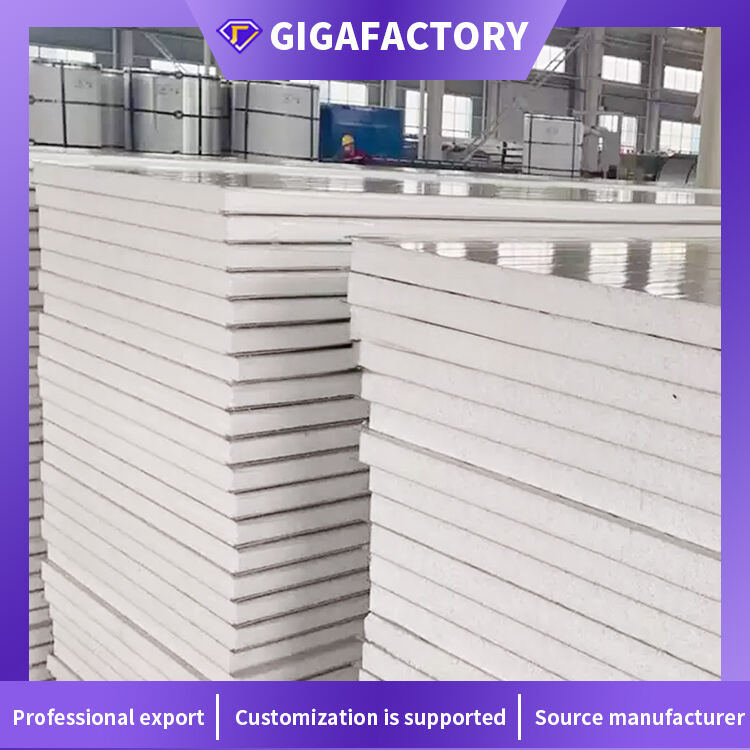

For the roof and wall cladding, both sandwich panels and single-skin color steel sheets are viable options. Galvanized sheet metal, in particular, offers excellent protection against rust and corrosion, significantly extending the lifespan of the steel structure warehouse/workshop. Self-tapping screws are commonly employed to secure the panels, creating a tight and leak-proof seal. When using composite panels, the core materials such as polystyrene, glass wool, rock wool, or polyurethane provide superior thermal insulation, heat resistance, and fire-retardant properties, enhancing the energy efficiency and safety of the building. Alternatively, brick walls can be used for the structural enclosure, although they generally incur higher costs compared to galvanized steel roof and wall systems.

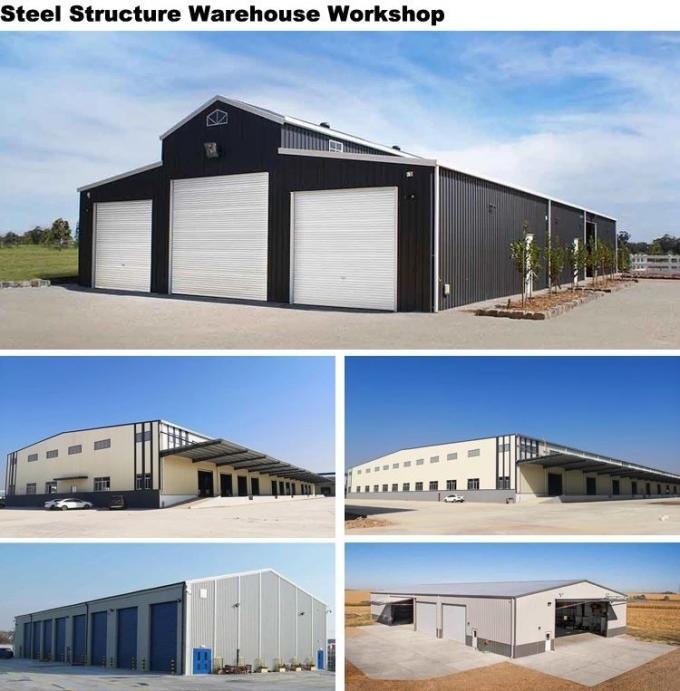

Steel structure warehouses find extensive applications across a wide range of industries, including large-scale manufacturing plants, storage facilities, supermarkets, entertainment complexes, and modular steel garages. Their versatility, durability, and cost-effectiveness make them an ideal solution for modern construction needs.

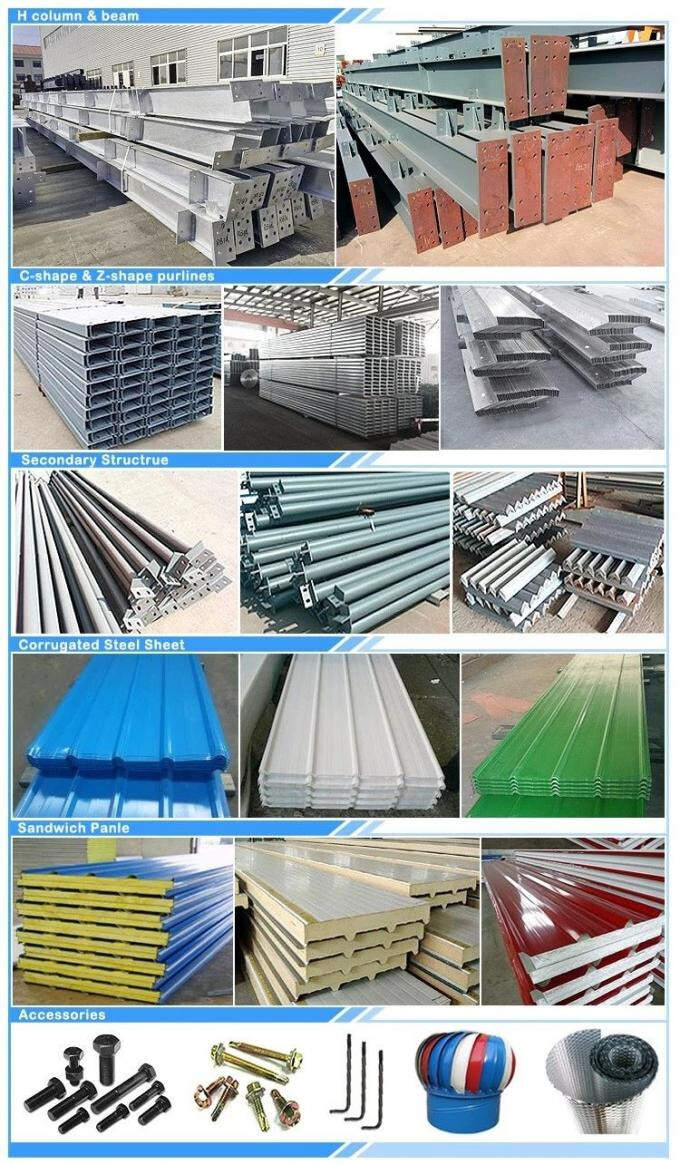

Steel structure workshop/warehouse main materials specification

| Items |

Specification |

| Main Steel Frame |

Column |

Q235, Q345 Welded H Section Steel |

|

Beam |

Q235, Q345 Welded H Section Steel |

| Secondary Frame |

Purlin |

C and Z purlin |

|

Knee brace |

Angle Steel |

|

Tie Rod |

Circular Steel Pipe |

|

Brace |

Round Steel Bar |

|

Vertical and Horizontal Support |

Angle Steel, Round Bar or Steel Pipe |

| Maintenance system |

Roof Panel |

EPS Sandwich Panel / Glass Fiber Sandwich Panel / |

| Rock Wool Sandwich Panel / Pu Sandwich Panel / Single Steel Roofing Sheet. |

|

Wall Panel |

Sandwich Panel / Corrugated Steel Sheet |

| Accessories |

Window |

Aluminum Alloy Window / PVC Window / Shutter |

|

Door |

Sliding door / Roller door / Swing Door |

|

Rainspout |

PVC |

| Live load on Roof |

Based on customers’ requirements. |

| Wind Resistance Grade |

According to the local meteorological conditions |

| Earthquake-resistance |

8 Grades |

| Structure Lifetime |

More than 50 years |

| Finishing Options |

Vast array of colors and textures available |

| Finishing Options |

Gray color, red color, white color, epoxy zinc etc, Or Galvanized. |

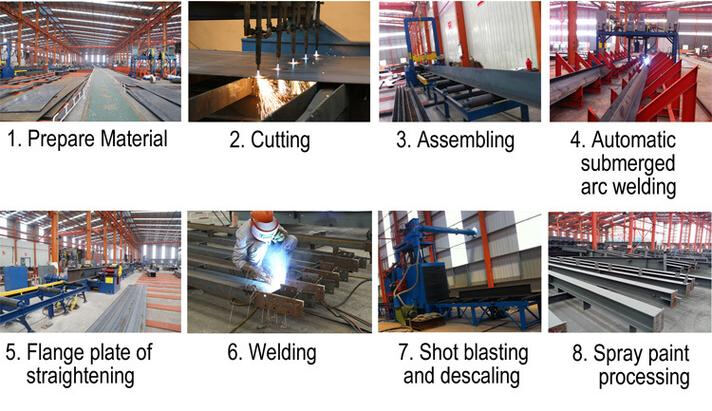

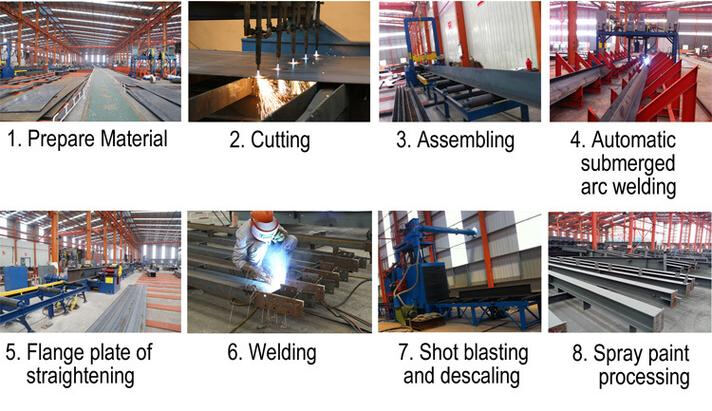

Steel Structure Warehouse/Workshop Project Processing Flows:

We have several advanced steel structure processing lines and professional welding team, who are well educated and have welding certificate, most important is that most of them have over 25 years working experiences.

Steel Structure Export Packing and Loading

Flat packed into 40'HQ or separate into 40'OT.

Reference Steel Structure Project Case

1. Where is your factory?

Our factory was located in Foshan City, Sanshui District, it’s about 40 minutes away from Guangzhou airport.

2. What are your main products?

Our main products including steel structure warehouse/workshop, container house, prefab house, and color steel sandwich panels?

3. Do you offer designing service for us?

Yes, we could design full solution drawings as your requirements. By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) and etc. we can design complex industrial building like office mansion, super marker, auto dealer shop, shipping mall, 5 star hotel.

4. What is the delivery time?

Delivery time depends on order quantities. In general the delivery time to nearest seaport in China will be within 30 days after deposit has been confirmed.

5. How about your quality control?

We have a professional quality inspection team and advanced testing equipment. In addition, we support third-party testing, such as SGS, TUV and so on.

6. Can you send engineers or whole team to install my project?

We will provide you with detailed installation drawings If necessary, we will send professional engineers for guidance and experienced technical workers to help with installation.

7. What’s your payment terms?

Generally practise is 30% T/T deposit and balance amount should be paid before delivery. For bulk order, 30% T/T deposit and balance amount paid by LC is acceptable.