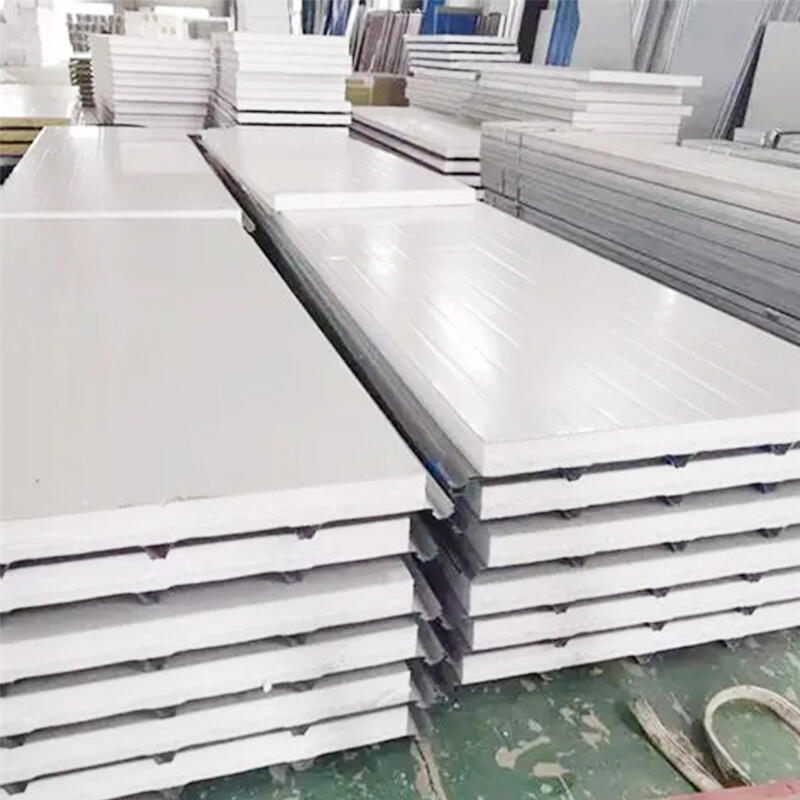

polyurethane insulated panel

Polyurethane insulated panels represent a cutting-edge building material that combines superior thermal insulation with structural integrity. These innovative panels consist of a polyurethane foam core sandwiched between two facing materials, typically made of steel or aluminum. The unique composition delivers exceptional thermal resistance values (R-values), making them ideal for temperature-controlled environments. The panels' design incorporates an interlocking joint system that ensures airtight connections and simplified installation processes. These panels serve multiple functions in construction, from creating efficient cold storage facilities to developing energy-saving building envelopes. The polyurethane core's closed-cell structure provides excellent moisture resistance and prevents thermal bridging, while the metal facings offer durability and weather protection. In modern construction, these panels have become increasingly popular due to their versatility, being suitable for walls, roofs, and partition applications. The manufacturing process involves continuous production lines where liquid polyurethane components are injected between the facing materials and expand to create a rigid, unified panel. This results in consistent quality and precise dimensional control, ensuring reliable performance across various applications.