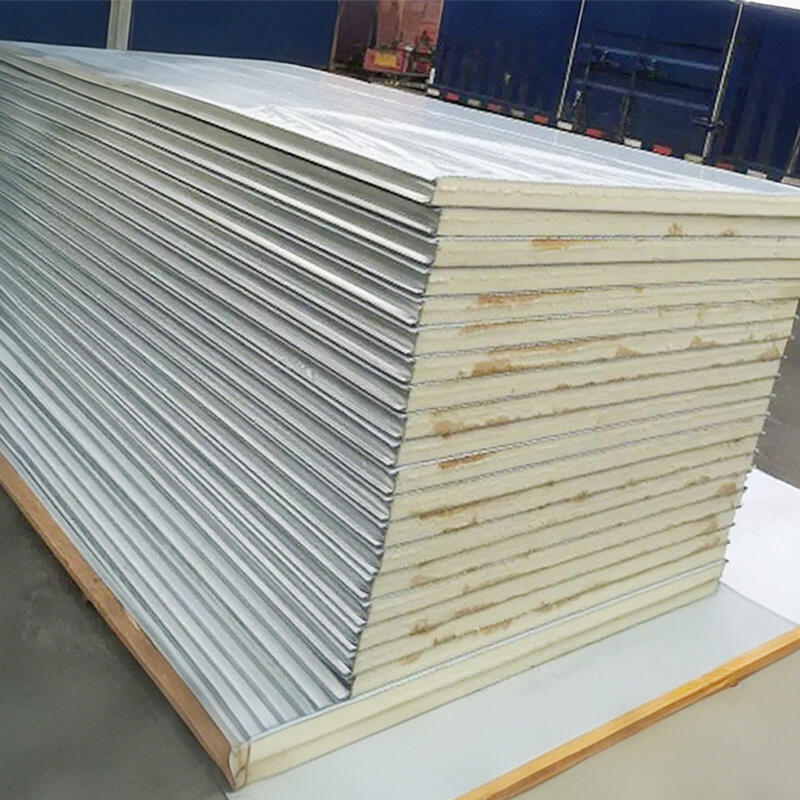

sandwich pu panel

Sandwich PU panels represent a revolutionary building material that combines durability, insulation, and cost-effectiveness in a single solution. These panels consist of two high-strength facing materials, typically steel or aluminum sheets, bonded to a core of polyurethane foam. This structural composition creates a robust yet lightweight building component that offers superior thermal insulation properties. The panels are manufactured through a continuous production process where liquid polyurethane is injected between the facing materials and expands to create a solid, uniform core. This advanced manufacturing technique ensures consistent quality and structural integrity throughout the panel. The versatility of sandwich PU panels makes them ideal for various applications, including industrial buildings, cold storage facilities, commercial structures, and agricultural buildings. Their excellent thermal properties help maintain stable indoor temperatures while reducing energy consumption and associated costs. The panels feature tongue and groove joining systems that enable quick and efficient installation, significantly reducing construction time compared to traditional building methods. Additionally, these panels offer excellent fire resistance, moisture protection, and sound insulation properties, making them a comprehensive solution for modern construction needs.